Introduce

In today’s rapidly evolving industrial landscape, materials that offer strength, durability, and versatility are in high demand. One such material that has gained significant traction is fiberglass mesh. This article aims to explore the multifaceted applications of fiberglass mesh, addressing common questions and shedding light on its importance in various industries. Whether you are a manufacturer, trader, or engineer, understanding the capabilities of fiberglass mesh can open up new possibilities for your projects and products.

Why is Fiberglass Mesh Banned?

One of the main reasons for banning fiberglass mesh is the potential health risks associated with exposure to fiberglass fibers. Another concern is the environmental impact of fiberglass mesh. While it is durable and long-lasting, it is not biodegradable. Improper disposal of fiberglass mesh can lead to pollution and environmental degradation.In response to these concerns, some regions have imposed bans or restrictions on the use of fiberglass mesh.However, it is important to note that these restrictions are not universal. In many regions, fiberglass mesh remains a widely used and valuable material, provided that proper safety measures are followed.

What is Fiberglass Mesh Used For?

Fiberglass mesh fabric is widely used in various industries due to its excellent quality:

Construction and Building Materials

One of the most prominent applications of fiberglass mesh is in the construction industry. It is commonly used as a reinforcing material in wall systems, particularly in areas prone to cracking and structural stress.

Automotive Industry

The automotive industry has also embraced fiberglass mesh for its lightweight and robust properties. It is used in the production of body panels, bumpers, and other components that require both strength and flexibility. Fiberglass mesh can be molded into complex shapes, making it ideal for creating custom parts and accessories.

Aerospace and Marine Applications

The aerospace and marine industries rely heavily on fiberglass mesh due to its high strength-to-weight ratio and excellent resistance to environmental factors. In aerospace, fiberglass mesh is used in the construction of aircraft fuselages, wings, and other structural components.

Insulation and Mattresses

In the mattress industry, fiberglass mesh is sometimes used as a fire barrier. It is placed between the foam layers and the outer cover to meet fire safety regulations without compromising comfort.

Sports and Recreation

In the sports and recreation industry, fiberglass mesh is used in the production of equipment such as surfboards, kayaks, and bicycles.

What are the Characteristics of Fiberglass Mesh?

Quality fiberglass mesh boasts several key characteristics:

High Strength

Fiberglass mesh is known for its exceptional tensile strength, making it a reliable choice for reinforcement purposes.

Flexibility

It offers flexibility without compromising its durability, allowing it to adapt to different shapes and surfaces.

Corrosion Resistance

Fiberglass mesh is resistant to corrosion, ensuring long-term performance even in harsh environments.

Lightweight

Despite its strength, glass fiber mesh is lightweight, making it easy to handle and install.

Is a Higher Fiberglass Mesh Count Better?

In general, a higher fiberglass mesh count means a finer weave and a smoother surface. However, the choice of mesh count depends on your specific application. A higher count is often preferred for projects that require a smoother finish, such as mosaic tile work, while coarser meshes are suitable for applications like concrete reinforcement.

What are the Different Types of Fiberglass Mesh?

Fiberglass mesh is a versatile material, and there are several different types of fiberglass mesh, each designed for a specific use based on factors such as weave pattern, weight, and coating. Here are some common types of fiberglass mesh:

This type of fiberglass mesh is treated with an alkali-resistant coating and is usually made of acrylic or latex. It is commonly used in cement-based applications such as stucco and plaster to provide reinforcement and prevent cracking.

This mesh has an adhesive backing that sticks easily to surfaces without the need for additional adhesive. It is often used in drywall and drywall installations to reinforce seams and seams.

Heavy-duty fiberglass mesh has a thicker weave and higher weight, making it suitable for applications requiring extra strength and durability. It is commonly used on roofs, floors and as the base material for mosaic tiles.

This type of fiberglass mesh has a finer weave and is used in applications that require a smoother surface, such as wall repair or as a backing for decorative veneer.

This type of mesh is designed to withstand high temperatures and is often used in industrial applications such as furnace or oven insulation.

This type of mesh is specifically designed for use with window and door screens, providing insect protection while allowing airflow and visibility.

This is a narrow tape of fiberglass mesh with an adhesive backing. It is commonly used to reinforce joints and seams in drywall and other building materials.

The choice of fiberglass mesh depends on the specific requirements of the project, including the type of material used, expected stresses and environmental factors. Different types of fiberglass mesh offer varying levels of strength, flexibility, and resistance to different chemicals and conditions. Therefore, it is important to choose the right type of fiberglass mesh for your specific application.

How Do I Choose the Right Mesh?

Choosing the right fiberglass mesh materials involves considering factors like mesh count, weight, and the specific requirements of your project. Aiswix, with over 20 years of experience in the textile industry, can provide expert guidance to ensure you make the best choice for your application.

How Do You Install Fiberglass Mesh?

Proper installation is crucial for the effectiveness of fiberglass mesh. It typically involves cleaning and preparing the surface, applying adhesive, embedding the mesh, and finishing with a topcoat or adhesive. Aiswix offers not only high-quality fiberglass mesh but also installation support to ensure your project’s success.

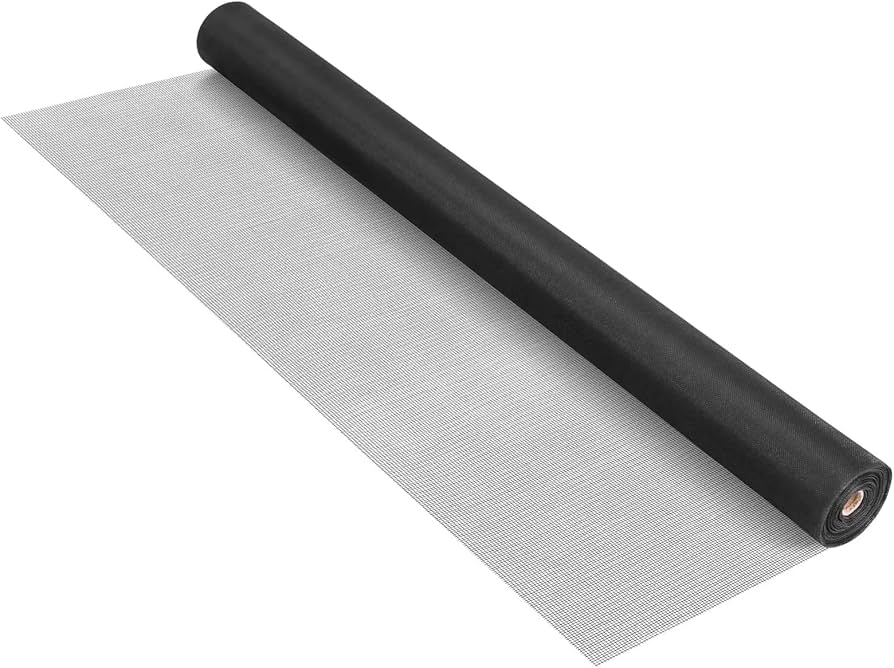

How Long Does Fiberglass Mesh Last?

Fiberglass mesh roll is known for its durability and long lifespan. When installed correctly, it can last for decades, even in challenging environments. Its resistance to corrosion and environmental factors makes it a reliable choice for long-term projects.

What are the Advantages of Aiswix Fiberglass Mesh?

As a leading manufacturer in China, Aiswix prioritizes customer satisfaction and offers high-quality fiberglass mesh products that meet and exceed industry standards.

Quality and Consistency

Aiswix’s fiberglass mesh is renowned for its quality and consistent performance, making it the top choice for those who value reliability.

Timely Delivery

Aiswix understands the importance of timely delivery, and its customer-centric approach ensures that clients receive their orders on schedule.

Expert Customer Service

Aiswix works closely with clients to address any issues or challenges, ensuring a seamless experience from inquiry to installation.

Competitive Pricing

Despite its high-quality products and exceptional service, Aiswix maintains competitive pricing, providing excellent value for clients.

In Conclusion

In conclusion, fiberglass mesh is a versatile and dependable material used in various industries for reinforcement, waterproofing, and more. Aiswix, with its commitment to quality, reliability, and customer satisfaction, is a trusted partner for businesses worldwide. Whether you’re in need of fiberglass mesh for concrete reinforcement, mosaic tiles, or any other application, Aiswix has you covered.

Are you ready to explore the world of fiberglass mesh and discover how it can benefit your projects? Contact Aiswix today, and let us be your partner in quality and reliability!