Introduce

At Aiswix, we have over 20 years of experience in the fiberglass industry and specialize in producing first-class fiberglass mats. In this blog post, we will take a deep dive into the importance of chopped strand mats and guide you through the key factors to consider when choosing the right strand mat for your product. Whether you are an experienced manufacturer or new to the industry, this comprehensive guide will help you make informed decisions and optimize your production process.

Why Chopped Strand Mat Is Important for Your Products

Chopped Strand Mat (CSM) is a nonwoven material made of randomly oriented bundles of glass fibers bonded together by a binder. It is widely used in the manufacture of composites due to its outstanding strength, durability, and ease of use. Here are some of the reasons why chopped strand mat is essential for your products:

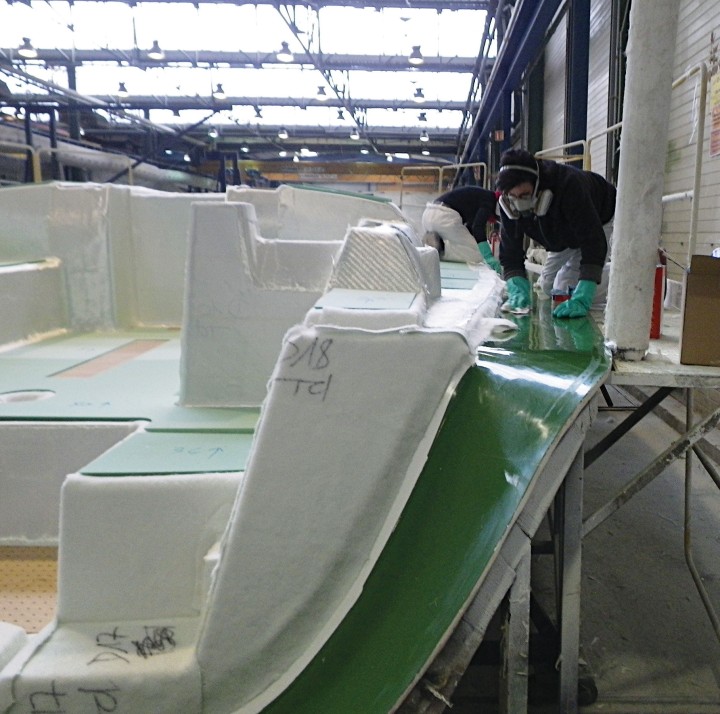

- Versatility: CSM can be used in a variety of applications, including shipbuilding, automotive parts, swimming pools, and tanks. Its adaptability makes it a top choice for many industries.

- Cost-effectiveness: Compared to other reinforcement materials, chopped strand mat offers a cost-effective solution without compromising on quality.

- Easy to handle: The random orientation of the fibers makes it easy to cut, shape, and mold, making it ideal for complex designs.

- Reinforcement Strength: When combined with resin, CSM has excellent mechanical properties, including high tensile strength and impact resistance.

Key Factors to Consider When Selecting Chopped Strand Mat

There are several factors to consider when choosing the right fiberglass chopped strand mat for your product. Here are some key aspects to keep in mind:

Material Quality

Make sure the fiberglass mat is made from high-quality E-glass or C-glass fibers, which offer excellent strength and durability.

Check that the fiber distribution is consistent and the binder application is even to avoid weak spots in the final product.

Weight and Thickness

The weight of the mat is usually measured in grams per square meter (g/m²) and determines the

mat. For example, fiberglass mat 300 refers to a mat that weighs 300 g/m².Choose a weight that matches the requirements of your product. Heavier mats offer greater strength but may be more difficult to handle.

Binder Type

The binder used in the mat plays a critical role in its performance. Common binders include polyester, vinyl ester, and epoxy-compatible binders.

Make sure the binder is compatible with the resin system you plan to use.

Application Method

Consider how the mat will be applied during the manufacturing process. For hand layup, lighter mats may be easier to handle, while for machine applications, heavier mats may be more appropriate. Chopped strand mats can be used in applications such as tanks, planters, swimming pools, boat building, pipe linings, sanitary ware, fiberglass doors, fiberglass manhole covers, fiberglass chairs, water slides, truck bodies, automotive parts, roof waterproofing, waterproof ceilings, tank waterproofing, etc.

Work with reputable suppliers such as Aiswix who can provide consistent quality, timely delivery, and excellent customer service.

What are the characteristics of chopped strand mat materials?

Understanding the characteristics of glass fiber chopped strand mat materials is essential to making an informed choice. Here are some of the key features:

High strength-to-weight ratio

CSM provides excellent strength without adding much weight to the final product. Aiswix’s chopped strand mat uses high-quality E-glass fibers and is treated with a special process to ensure even fiber distribution and higher strength. Compared with ordinary chopped strand mats, Aiswix chopped strand mats have a tensile strength of up to 300 MPa, which is 15%-20% higher than ordinary chopped strand mats, and an impact strength of 120 kJ/m², which is significantly better than the industry average.

Corrosion resistance

Glass fiber itself is corrosion-resistant and is very suitable for use in harsh environments. Aiswix’s chopped strand mat has a special coating on the fiber surface to further enhance its corrosion resistance. Whether in acidic, alkaline or salt spray environments, Aixswix’s chopped strand mat can maintain long-term stability and extend the service life of the product.

Thermal insulation

CSM has good thermal insulation properties, which is very useful in certain applications. Aiswix’s chopped strand mat significantly improves thermal insulation performance by optimizing fiber density and binder formulation. Aiswix chopped strand mat has a thermal conductivity as low as 0.04 W/m·K, which is 10%-15% lower than ordinary chopped strand mat. At 200°C, the thermal insulation performance of Aiswix products remains stable, and heat transfer is reduced by 20%, making it an ideal choice for applications such as building insulation and pipe insulation.

Fire resistance

Glass fiber is non-flammable and can withstand high temperatures, making it a safe choice for flammable environments. Aiswix’s chopped strand mat uses a high-temperature resistant binder. Aiswix chopped strand mat

can withstand short-term high temperatures of up to 600°C and long-term use temperatures of up to 200°C. Aiswix’s products have passed a number of international fire protection certifications and are suitable for fields such as aerospace and rail transportation that require extremely high fire resistance.

Chemical resistance

CSM can resist a variety of chemicals to ensure service life in corrosive environments. Aiswix’s chopped strand mat has been specially chemically treated to resist erosion by a wider range of chemicals, including strong acids, strong alkalis and organic solvents. Aiswix‘s products perform well in applications such as chemical corrosion protection and tank lining, providing customers with a longer service life of 30%-40% longer than ordinary chopped strand mats and lower maintenance costs.

How to Use Fiberglass Chopped Strand Mat?

Effectively using fiberglass chopped strand mat requires proper technique and attention to detail. Here is a step-by-step guide:

Preparation: Make sure the surface where the mat will be used is clean and free of contaminants.

Cutting: Use sharp scissors or a utility knife to cut the mat into the desired size and shape. For example, a fiberglass cutting mat tool can make this process easier.

Laying Up: Lay the mat on the surface and use a brush or roller to evenly apply the resin. Make sure the resin completely saturates the mat.

Curing: Allow the resin to cure according to the manufacturer’s instructions. This may involve room temperature curing or the use of heat for faster results.

Finishing: Once cured, the surface can be sanded, painted, or coated as desired.

Practical considerations for contractors, distributors and manufacturers

It is crucial for contractors, distributors and manufacturers to understand the needs of their customers. Here are some practical considerations:

Product performance matches the project: Contractors need to ensure that the strength, corrosion resistance, thermal insulation and other properties of chopped strand mat can meet the specific requirements of the project. For example, in a chemical project, chemical resistance may be the primary consideration; while in a building insulation project, thermal insulation is more important. Aiswix‘s chopped strand mat offers a variety of specifications and performance options, such as fiberglass mat 300 and emulsion chopped strand mat, to meet the needs of different projects.

Ease of use and construction efficiency: Contractors want materials that are easy to cut, lay and shape to reduce construction time and cost. Aiswix’s chopped strand mat has uniform fiber distribution and moderate binder content, ensuring easy operation during construction and reducing the generation of bubbles and dry spots. Quality stability: Contractors need to ensure that the quality of each batch of chopped strand mat is consistent to avoid unexpected problems during construction. Aiswix ensures high consistency of products through a strict quality control process.

Technical support and after-sales service: Contractors may encounter technical problems during the construction process, so they need suppliers to provide timely technical support and solutions. Aiswix‘s has a professional technical team that can provide customers with all-round support from selection to construction.

Market demand and product diversity: Distributors need to understand market demand and choose best-selling chopped strand mat products. Aiswix provides a variety of specifications and types of chopped strand mats, such as fiberglass felt and fiberglass mat 300, which can meet the needs of different customers. Distributors can also customize special specifications of products to Aiswix according to market demand to enhance market competitiveness.

Inventory management and delivery time: Distributors need to ensure sufficient inventory while avoiding excessive inventory backlogs. Aiswix has an efficient production and logistics system that can ensure fast delivery and help distributors optimize inventory management.

Profit margin and pricing strategy: Distributors pay attention to the profit margin of products. Aiswix provides competitive prices through large-scale production and lean management to help distributors obtain higher profits.

Brand reputation and customer trust: Distributors who choose to work with Aiswix can win the trust and long-term cooperation of customers with the help of our brand reputation and high-quality products.

Material performance and product quality: Manufacturers need to ensure that the performance of chopped strand mat can meet the requirements of the final product. For example, automotive parts manufacturers may require chopped strand mats with high strength and high corrosion resistance, while ship and swimming pool manufacturers are more concerned about the fatigue resistance of the material. Aiswix’s chopped strand mats are rigorously tested to ensure that its mechanical properties, chemical resistance and fire resistance are at the industry-leading level.

Production efficiency and cost control: Manufacturers want materials that are easy to process, improve production efficiency and reduce scrap rates. Aiswix’s chopped strand mats have uniform fiber distribution and moderate binder content, ensuring easy operation in processes such as molding and pultrusion, reducing waste in production. In addition, Aiswix offers competitive prices to help manufacturers reduce raw material costs.

Supply chain stability: Manufacturers need to ensure a stable supply of raw materials to avoid production interruptions. Aiswix has strong production capacity and a complete logistics system to ensure on-time delivery and support manufacturers’ continuous production.

Customized service: Manufacturers may require specific specifications of chopped strand

mat to meet the requirements of their production process. Aiswix provides highly customized services, adjusting the gram weight, width, length and binder type according to customer needs to ensure that the product perfectly matches their production line. Environmental protection and compliance: With increasingly stringent environmental regulations, manufacturers need to ensure that raw materials meet environmental standards. Aiswix‘s chopped strand mat uses environmentally friendly binders and complies with international standards such as RoHS and REACH, helping manufacturers meet environmental requirements.

Aiswix: Your Trusted Fiberglass Chopped Strand Mat Supplier

At Aiswix, we pride ourselves on being a customer-centric company. With over 20 years of experience in the fiberglass industry,

we have five R&D production lines, complete infrastructure,covering an area of 250,000 square meters, and an annual production capacity of up to 1 million tons. Among them, our best-selling products, chopped strand mat, have an annual production capacity of 250,000 tons and chopped strands have an annual production capacity of 200,000 tons. These figures not only reflect our production capacity, but also highlight our leading position in the industry.

Aiswix has obtained the prestigious Alibaba Gold Supplier status and has a reputation for high-quality products and excellent customer service with CE certification, SGS certification and ISO9001 certification. Our fiberglass chopped strand mat is manufactured to the highest standards to ensure reliability and consistency for your production needs. Whether it is chopped strand mat or chopped strand, we strictly control every production link to ensure that the product performance reaches the international leading level.

We deeply understand our customers’ pain points, such as timely delivery and quality control. To this end, we ensure that their specific needs are met through strict production standards and close cooperation with customers. Whether you are a manufacturer, trader or engineering company, you can trust Aiswix to be your

reliable partner in the fiberglass industry. We are committed to providing customers with high-quality products and professional service support to help them succeed in their respective fields.

Conclusion

Choosing the right Fiberglass Chopped Mat for your product is a critical decision that can impact the quality, durability, and performance of your final product. By considering factors such as material quality, weight, binder type, and application method, you can make an informed choice that meets your specific needs.

At Aiswix, we are committed to providing high-quality fiberglass mats and exceptional customer service. Whether you need fiberglass felt, fiberglass mat 300, or emulsion chopped strand mat, we have the expertise and resources to support your business. Contact us today to learn more about our products and how we can help you achieve your manufacturing goals.