Introduce

In the world of composite materials, Fiberglass chopped strand mat stands out as a cornerstone for enhancing product performance and durability. This versatile material is engineered to provide superior reinforcement, making it an essential component across a wide range of industries. From automotive and marine applications to construction and beyond, the importance of fiberglass chopped strand mat cannot be overstated. It is the backbone of modern manufacturing, offering a blend of strength, flexibility, and reliability that few other materials can match.

In this guide, we’ll explore why chopped strand mat is essential for your brand, how to choose the right product, and why Aiswix is your ideal partner for all your fiberglass needs.

Why Fiberglass Chopped Strand Mat is Essential for Your Brand?

When it comes to enhancing product performance, Fiberglass chopped strand mat is unparalleled. It offers a unique combination of strength, thermal resistance, and chemical stability that makes it ideal for a variety of applications. Whether you are in the automotive, marine, or construction industry, the multifunctionality of fiberglass chopped strand mat ensures that it can meet your specific needs.

For instance, in the marine industry, fiberglass chopped strand mat is crucial for manufacturing boat hulls and decks. Its high strength-to-weight ratio and resistance to corrosion make it the perfect material for withstanding harsh maritime conditions. In the automotive sector, it is used to produce lightweight yet durable components, contributing to fuel efficiency and overall vehicle performance. In construction, it reinforces structures, providing long-lasting durability and resistance to environmental factors.

By choosingFiberglass chopped strand mat, you are investing in a material that not only enhances the performance of your products but also ensures their longevity and reliability. This is why our clients, Hans, a 45-year-old R&D manager at a major American company, trust Aiswix for their fiberglass needs. They value the consistency and reliability of our products, knowing that we prioritize quality and customer satisfaction.

Key Factors to Consider When Choosing Chopped Strand Mat

Selecting the right Fiberglass chopped strand mat involves several critical considerations. Understanding these factors will help you make an informed decision that aligns with your specific requirements.

Specifications and Performance

The specifications of your fiberglass chopped strand mat are crucial in determining its effectiveness. Key parameters include:

- Weight (grams per square meter): This affects the mat’s strength and flexibility. Higher weights generally provide greater reinforcement.

Fiber Length: Shorter fibers offer more flexibility, while longer fibers enhance strength.

Density: Higher density mats provide better reinforcement but may be less flexible.

- Binder Type: The type of binder used can impact the mat’s performance. Common binders include powdered and emulsion types, each with unique properties.

At Aiswix, we offer a wide range of specifications to meet diverse needs. Our continuous strand mat and continuous filament mat options provide consistent reinforcement, while our Powder Fiberglass Mat and Emulsion Fiberglass Mat offer specific advantages depending on your application.

Durability and Environmental Adaptability

Durability is a key consideration when choosing fiberglass chopped strand mat. The material must withstand various environmental conditions, including exposure to UV light, moisture, and chemicals. Aiswix’s mats are designed to maintain their integrity under harsh conditions, ensuring long-term performance and reliability.

Customization Options for Fiberglass Chopped Strand Mat

At Aiswix, we understand that one size does not fit all. That’s why we offer extensive customization options to meet your unique needs. Our chopped strand mat supplier solutions include:

- Custom Specifications: We can tailor the weight, fiber length, and density to match your specific requirements.

- Binder Types: Choose from Powder Fiberglass Mat or Emulsion Fiberglass Mat, depending on your application’s needs.

- Performance Enhancements: We can optimize our mats for specific performance characteristics, such as increased thermal resistance or chemical stability.

Our commitment to customization ensures that you receive a product perfectly suited to your needs. Whether you require a lightweight mat for automotive applications or a high-density mat for construction, Aiswix has the solution. Our clients appreciate this flexibility, knowing that we prioritize their unique requirements.

Practical Considerations for Real-World Applications

In practical applications, the ease of use and specific operational considerations of Fiberglass Chopped Strand Mat (CSM) are crucial for ensuring material performance and construction quality. Below are the key operational points and considerations for using fiberglass chopped strand mat in various applications:

Fiberglass Chopped Strand Mat is widely used in the manufacturing of composite materials, especially in combination with polyester and vinyl ester resins. The random fiber orientation of the mat provides isotropic strength, making it suitable for applications requiring uniform performance. During application, ensure the proper ratio of resin to mat is maintained. For example, a 600g/m² mat is recommended to be used with approximately 1.5kg of catalyzed polyester resin. Additionally, the working environment should be kept dry, with temperatures between 15-30°C to ensure optimal curing.

Operational Considerations:

- Ensure the mat is dry before use to avoid affecting the resin’s wettability.

- Wear appropriate personal protective equipment (PPE), such as gloves, goggles, and masks, during application.

- Conduct operations in a well-ventilated area to avoid inhaling glass fiber dust.

Fiberglass Chopped Strand Mat is commonly used in the marine industry for reinforcing boat hulls, decks, and cabin structures. Its corrosion resistance and formability make it an ideal material. For example, in hull repair, laminating and impregnating the mat can effectively restore the structural integrity and strength of the boat.

Operational Considerations:

- When working in damp environments, apply a primer to the substrate first to enhance adhesion.

- For hull repairs, it is recommended to use double layers of mat to improve durability.

- Ensure the resin fully saturates the fibers during construction to avoid air bubbles, which can compromise structural performance.

Fiberglass Chopped Strand Mat is used in the automotive industry to produce lightweight yet strong components such as engine covers, seats, and body panels. Its high strength-to-weight ratio helps improve fuel efficiency and vehicle performance.

Operational Considerations:

- In automotive interior applications, ensure the mat is thoroughly mixed with resin to achieve uniform filler material.

- Avoid fiber fluffing during operations. It is recommended to work in a closed environment to reduce health risks to operators.

- During the molding process of automotive components, strictly control the ratio of resin to mat to ensure the mechanical properties of the parts.

Fiberglass Chopped Strand Mat is widely used for lining and coating storage tanks, providing corrosion resistance and structural reinforcement. Its excellent chemical stability and durability make it an ideal lining material.

Operational Considerations:

- Before construction, ensure the tank’s inner wall is dry and free of impurities to ensure good adhesion between the mat and the substrate.

- When lining the inner wall of a storage tank, it is recommended to use multiple layers of mat and saturate each layer with resin to enhance protection.

- Wear appropriate protective gear during operations to avoid direct contact between glass fibers and the skin.

Fiberglass Chopped Strand Mat is used for reinforcing swimming pool liners, providing corrosion resistance and waterproofing. Its good formability allows it to adapt to complex pool structures.

Operational Considerations:

- When lining swimming pools, ensure the mat is fully saturated with resin to avoid bubbles and voids.

- Keep the construction environment dry to avoid moisture affecting the resin’s curing.

- Wear protective gear during operations to avoid irritation to the skin and respiratory tract from glass fibers.

By following these operational considerations and leveraging the ease of use of Fiberglass Chopped Strand Mat, you can ensure optimal performance and construction quality, providing reliable reinforcement solutions for your projects.

Aiswix: Your Trusted Partner for Fiberglass Chopped Strand Mat

When it comes to choosing a chopped strand mat supplier, Aiswix stands out as a trusted partner.We have the capacity and expertise to meet your needs. Our commitment to quality and customer service sets us apart from other suppliers.

Company Background

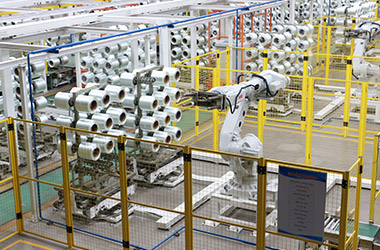

Aiswix has been at the forefront of the fiberglass industry for over 20 years. Our state-of-the-art manufacturing facilities ensure consistent production quality, while our experienced team provides unparalleled technical support. We have a strong track record of exporting our products globally, with a significant presence in Europe, Asia, and the Americas.

Quality Control and Global Supply

Our rigorous quality control processes ensure that every batch of Fiberglass chopped strand mat meets the highest standards. We work closely with our clients to ensure timely delivery and stable pricing, prioritizing their needs above market trends. Our dedication to customer satisfaction is evident in our long-term partnerships, such as our decade-long relationship with one of the largest companies in the USA.

Customer-Centric Approach

At Aiswix, we prioritize a customer-centric approach. We understand that each client has unique requirements, and we are committed to providing high-quality, one-stop services that meet those needs. Our clients, like Hans, appreciate our reliability and the close collaboration we offer in solving any issues that arise.

In Conclusion

Choosing the right Fiberglass chopped strand mat is crucial for enhancing your product’s performance and ensuring its longevity. Aiswix offers a comprehensive range of high-quality mats, tailored to meet your specific needs. Our commitment to quality, customization, and customer service makes us the ideal partner for your fiberglass requirements.

We invite you to contact Aiswix today to learn more about our products and how we can provide a customized solution for your brand. Experience the difference that Aiswix’s Fiberglass chopped strand mat can make in your manufacturing processes.