Introduce

In the ever-evolving world of automotive manufacturing, the materials used play a pivotal role in determining the quality, durability, and performance of the final product. Among the myriad of materials available, Fiberglass Chopped Strand Mat (CSM) has emerged as a standout choice for manufacturers worldwide. At Aiswix, we have been at the forefront of the fiberglass industry for over two decades, and our expertise has shown us time and again why fiberglass chopped strand mat roll is indispensable in automotive manufacturing.But why exactly is Fiberglass Chopped Strand Mat the best choice for automotive manufacturing? What makes it stand out from other materials? In this blog post, we will delve deep into the world of fiberglass mats, exploring their importance, applications, and benefits in the automotive industry. We will also address some common questions and concerns, providing you with a comprehensive understanding of why Fiberglass Chopped Strand Mat should be your go-to material for automotive manufacturing.

Importance of Chopped Glass Mat for Automotive Manufacturing

The automotive industry is one of the most demanding when it comes to material selection. Vehicles must be lightweight yet strong, durable and cost-effective, and able to withstand a wide range of environmental conditions. Chopped Glass Mat (CSM) meets all of these requirements and more, making it an indispensable material in automotive manufacturing.

High Strength and Durability

Despite its low weight, chopped glass mat does not compromise on strength. The random orientation of the glass fiber strands gives the material excellent tensile and flexural strength, allowing it to withstand tremendous loads and impacts. This is especially important for automotive parts that are subject to stress and strain, such as body panels, chassis components, and underbody guards. The durability of glass fiber CSM ensures that these parts remain intact and function properly even in harsh conditions.

Corrosion Resistance

Vehicles are often exposed to harsh environmental conditions, including rain, snow, and road salt, which can cause traditional materials such as steel to corrode over time. Chopped glass mat, however, is highly resistant to corrosion. This property ensures that automotive parts made from fiberglass CSM remain in top condition for many years, reducing the need for frequent replacement and repairs. The corrosion resistance of fiberglass CSM is particularly beneficial for underbody guards and other parts that are directly exposed to moisture and road debris.

Design Flexibility

The flexibility of fiberglass chopped strand mat allows it to be easily molded into complex shapes, making it ideal for manufacturing complex automotive parts. This design flexibility is especially valuable in the production of body panels, interior components, and other parts that require precise shaping and detailing. The ability to mold fiberglass CSM into a variety of shapes without compromising its structural integrity allows manufacturers to innovate and create more aerodynamic and aesthetically pleasing vehicle designs.

What are the applications of fiberglass chopped strand mat in automotive manufacturing?

Fiberglass chopped strand mat is used in a variety of applications in the automotive industry. Some of the most common uses include:

Body panels: Fiberglass CSM is often used to manufacture vehicle body panels. Its lightweight properties and high strength make it an ideal material for this application as it helps reduce the overall weight of the vehicle without compromising durability.

Interior components: Many vehicle interior components, such as dashboards, door panels, and seat backs, are made from fiberglass chopped strand mat. Its flexibility and easy formability make it ideal for creating complex shapes and designs.

Underbody guards: The underbody of a vehicle is subject to a lot of wear and tear, including impacts from road debris and moisture. Fiberglass CSM is used to manufacture underbody

guards that protect the vehicle from these elements, ensuring longevity and performance.

Structural components: In some cases, fiberglass chopped strand mat is used to manufacture structural components of a vehicle, such as chassis components and reinforcement beams. Its high strength and durability make it an excellent choice for these critical applications.

The Role of Aiswix Fiberglass Chopped Strand Mat Materials in Automobile Manufacturing

In the automotive manufacturing industry, the choice of materials has a crucial impact on the performance, safety, fuel efficiency and environmental impact of the vehicle. As a global leading supplier of glass fiber chopped strand mat, Aiswix is committed to providing high-quality, high-performance material solutions to automakers. The following are the main roles and advantages of Aiswix glass fiber chopped strand mat in automotive manufacturing.

High strength and durability

Glass fiber chopped strand mat has excellent mechanical properties, including high tensile strength (100-150 MPa) and impact resistance. These properties make it an ideal material for manufacturing body structural parts, chassis reinforcements and safety components. For example, Aiswix’s fiberglass csm450 performs well in crash tests and can effectively absorb impact energy to protect passenger safety.

Corrosion resistance

Aiswix glass fiber chopped strand mat has excellent corrosion resistance and can resist erosion by moisture, salt spray and chemicals. This feature makes it particularly suitable for manufacturing body floors, wheel arches and other parts exposed to harsh environments.

Design flexibility

Aiswix chopped strand mats are easy to shape and can be used to create complex geometric shapes and streamlined designs. This feature provides automotive designers with greater freedom to create more aerodynamic body designs. Through customized production, Aiswix can provide chopped strand mats that meet customers’ specific design needs.

The applicability and environmental protection of chopped strand mat

Chopped strand mat is a versatile material. Here are some examples of Aiswix fiberglass CSM being used in automotive, marine, industrial and other industries. Its environmental friendliness stems from its unique properties, such as recyclability and reduced carbon footprint.

Body Panels: Aiswix fiberglass CSM is used to make lightweight and durable body panels, reducing vehicle weight and improving fuel efficiency.

Interior Parts: Dashboards, door panels and seat backs made from Aiswix fiberglass CSM offer excellent strength and design flexibility.

Chassis Guards: Its corrosion resistance makes it ideal for chassis parts exposed to harsh road conditions.

Hulls and Deck: Aiswix fiberglass CSM is widely used in shipbuilding for its water resistance and superior strength.

Marine Infrastructure: It is also used in docks, buoys and other marine structures.

Chemial Tankcs: Its resistance to corrosive chemicals makes it a preferred material for industrial storage solutions.

Reinforcement in Composites: Aiswix Fiberglass CSM is often used as a reinforcement in composite manufacturing, increasing the strength and durability of the final product.

Fiberglass CSM is recyclable, meaning it can be broken down and reused to produce new materials. According to a study by the European Composites Industry Association (EuCIA), up to 70% of fiberglass waste can be recycled into new products, reducing landfill and conserving natural resources. For example, recycled fiberglass CSM can be used to produce building materials such as insulation boards or concrete reinforcement, further extending its lifecycle.

The production of fiberglass CSM produces fewer greenhouse gas emissions than traditional materials such as steel or aluminum. A study by the Fiberglass Industry Association found that in automotive applications, fiberglass CSM has a 30-40% lower carbon footprint than steel.

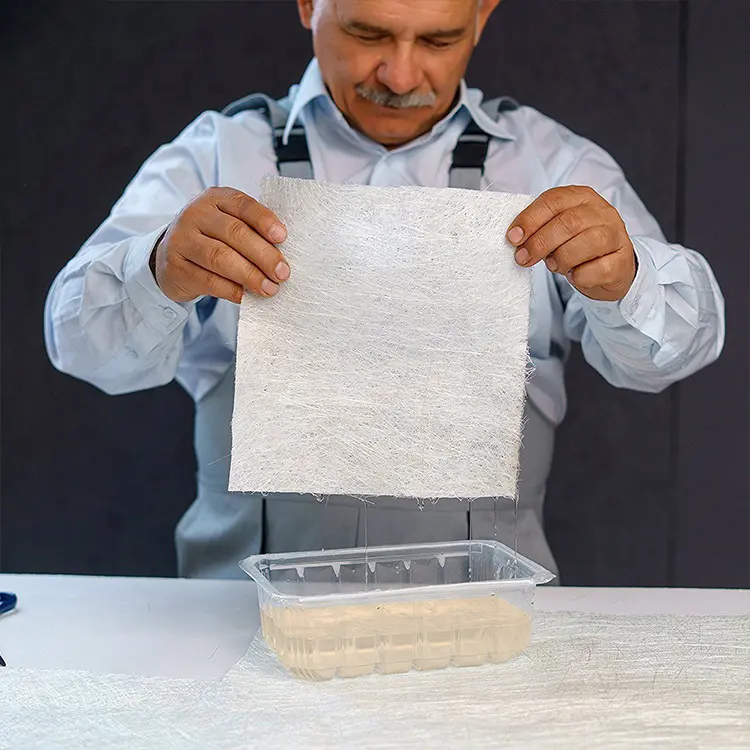

The wettability and mechanical properties of chopped strand mat

Wettability refers to the ability of a material to absorb and retain resin, which is critical to creating strong and durable composites. Glass Chopped Strand Mat is specifically designed to have excellent wettability to ensure optimal resin penetration and bonding. Here are the reasons why wettability is so important and why Glass CSM excels in this area:

Resin Absorption and Distribution

The random orientation of the glass fiber strands in Glass CSM creates a porous structure that allows resin to flow evenly throughout the material. This ensures complete saturation, which is critical to achieving uniform strength and durability in the final product. Aiswix Glass CSM can achieve resin absorption rates as high as 90-95%, significantly higher than other reinforcement materials.

Bond Strength

The high wettability of Glass CSM ensures a strong bond between the glass fiber strands and the resin matrix. This bond is critical to the structural integrity of the composite. Composites made with Aiswix Glass CSM have 20-30% higher interlaminar shear strength.

Thermal and Chemical Stability

Fiberglass CSM maintains its mechanical properties even under extreme temperatures and chemical exposure. Aiswix’s fiberglass CSM can withstand temperatures up to 300°C without significant degradation, making it suitable for high temperature applications

Real Applications and Data

Automotive Industry:A leading automotive manufacturer reported a 20% weight reduction and 15% improvement in crash performance measured by impact testing using fiberglass CSM for body panels.

Marine Industry:Marine manufacturers using fiberglass CSM for hulls and decks reported a 40% increase in efficiency

Customization: chopped strand mats of various sizes

Customization is critical to ensure that the material performs optimally in the intended application. At Aiswix, we pride ourselves on being able to offer fiberglass chopped strand mats in a wide range of sizes and specifications. Our customization capabilities include:

Various Sizes

We offer standard sizes of fiberglass CSMs, such as fiberglass chopped strand mat rolls, as well as sizes tailored for specific applications. Whether you require a small mat for a complex component or a large roll for high-volume production, we have what you need.

Weight and Thickness Options

Our fiberglass CSMs are available in a variety of weights and thicknesses, from lightweight mats such as 300 g/m² to heavier options such as fiberglass csm450. This enables customers to select the perfect mat for their application.

Resin Compatibility

We offer fiberglass CSMs that are compatible with a wide range of resins, including polyester, vinyl ester, and epoxy. Our team can recommend the best resin for your specific application to ensure optimal performance.

Pre-cut and pre-formed mats

For customers with specific design requirements, we offer pre-cut and pre-formed mats that match the exact dimensions of the final product. This reduces production time and ensures a perfect fit.

Specialized coatings

We can apply specialized coatings to the fiberglass CSM to enhance its properties, such as improving wettability, fire resistance or UV protection.

Commitment to quality

Our products are CE certified, SGS certified and ISO9001 certified, adhering to strict quality control standards to ensure that every product we deliver meets the highest industry standards.

State-of-the-art facilities

Our advanced manufacturing facilities enable us to produce fiberglass CSMs in a wide range of sizes and specifications with precision and consistency.

Customer-centric approach

At Aiswix, we prioritize our customers’ needs and work closely with them to develop custom solutions that meet their specific requirements.

Chopped strand mats for the automobile manufacturing industry

Why Fiberglass Chopped Strand Mat is Ideal for Engineers, Manufacturers, and Distributors

For Engineers: Design Flexibility and Performance

Engineers value fiberglass CSM for its ability to be molded into complex shapes without compromising strength or durability. The material’s high tensile strength (100-150 MPa) and impact resistance ensure that automotive parts can withstand harsh conditions, such as crashes and environmental exposure. Fiberglass CSM also has excellent fatigue resistance, making it suitable for parts subject to repeated stresses, such as suspension components and chassis reinforcement.

For Manufacturers: Cost-Effectiveness and Efficiency

The high wettability of Glass CSM ensures a strong bond between the glass fiber strands and the resin matrix. This bond is critical to the structural integrity of the composite. Composites made with Aiswix Glass CSM have 20-30% higher interlaminar shear strength.

For Distributors: High Demand and Marketability

Distributors find fiberglass CSM to be a marketable product as it is widely used in the automotive industry. Applications range from body panels and interior components to underbody shields and structural reinforcements. The material’s durability and corrosion resistance ensure that end users receive a high-quality product, resulting in repeat business and strong customer relationships. With the growing demand for lightweight, environmentally friendly materials, fiberglass CSM is positioned as a future-proof product in the automotive supply chain.

Aiswix’s Role in the Automotive Manufacturing Industry

Manufacturers benefit from the lightweight properties of fiberglass CSM, which reduces material costs and improves the fuel efficiency of vehicles. For example, replacing steel in body panels with fiberglass CSM can reduce vehicle weight by up to 20%, resulting in significant fuel cost savings. The material’s excellent wetting properties ensure efficient resin absorption, which reduces production time and labor costs. Manufacturers report that using fiberglass CSM reduces production time by 15-20% compared to other materials. Fiberglass CSM is also easy to handle and process, making it suitable for high-volume production lines.

Thermal and Chemical Stability

High-Quality Products:Aiswix provides premium fiberglass chopped strand mats that meet the highest industry standards. Our products such as Fiberglass CSM450 are known for their consistency, durability and performance.

Customized Options:We offer fiberglass CSM in a variety of sizes and specifications to meet the unique needs of our customers. Whether you need standard fiberglass chopped strand mat rolls or custom-sized mats, we can meet your requirements.

Technical Support:Our team of experts provides technical support to help customers optimize the use of fiberglass CSM. From resin selection to manufacturing processes, we ensure that customers get the best results.

Sustainable Solutions:Aiswix is committed to sustainable development. Our fiberglass CSM is recyclable and helps reduce the environmental impact of automotive manufacturing.

Global Presence:With more than 12 years of export experience, Aiswix has a strong global presence, supplying fiberglass CSM to customers in Europe, Asia, North America and South America. Our reliable logistics network ensures timely delivery of products around the world.

In Conclusion

In conclusion, Fiberglass Chopped Strand Mat is an indispensable material in the automotive manufacturing industry. Its unique properties, including high strength, flexibility, corrosion resistance, and environmental friendliness, make it the ideal choice for a wide range of applications.Whether you are manufacturing body panels, interior components, underbody shields, or structural parts, Fiberglass CSM offers the performance and durability you need. And with the ability to customize Fiberglass Chopped Strand Mat to meet your specific requirements, you can be confident that you are getting the best possible material for your automotive manufacturing needs.At Aiswix, we are committed to providing our clients with high-quality Fiberglass Chopped Strand Mat and exceptional customer service. If you are looking for a reliable fiberglass mat supplier, look no further than Aiswix. Contact us today to learn more about our products and how we can help you achieve your automotive manufacturing goals.

Are you ready to explore the world of fiberglass mesh and discover how it can benefit your projects? Contact Aiswix today, and let us be your partner in quality and reliability!