Unveiling the Wonders of Fiberglass Mesh

Fiberglass mesh – a material with countless applications and a range of properties, is a key player in a wide range of industries from architecture and automotive to art and design, its multifaceted nature proving its adaptability and strength. I’m here to demystify the mystery surrounding this extraordinary material and let’s get to the heart of the subject with a series of questions that will help you understand what quality fiberglass mesh is all about.

Is fiberglass mesh waterproof?

Fiberglass mesh is like your trusty umbrella in a rainstorm. Its innate waterproof properties make it an indispensable material in various industries. Imagine a construction site where fiberglass mesh waterproofing is applied to protect buildings from moisture intrusion. The mesh acts as a resilient barrier, keeping water at bay even in the most torrential downpours.

This waterproof quality extends to other applications as well. Picture a cozy patio shaded with glass fiber mesh roofing that not only shields you from the sun but also ensures a dry, rain-free experience. It’s this adaptability and ability to defy water that make fiberglass mesh a go-to choice when the elements are a concern.

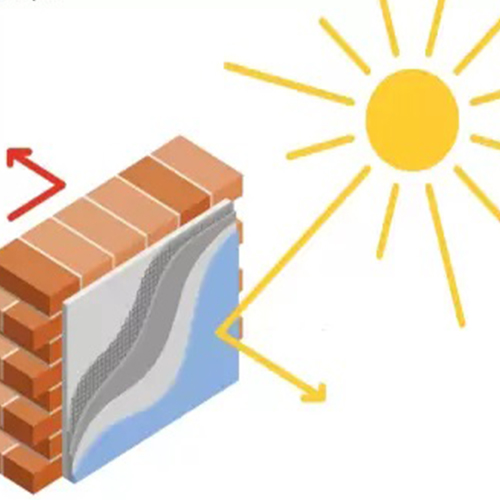

Does fiberglass mesh keep the sun out?

Absolutely, fiberglass mesh is your reliable sunshield. Imagine a scorching summer day, and you’re seeking refuge in a well-ventilated space. Here, fiberglass mesh fabric comes to your rescue. Its unique weave allows air circulation while effectively filtering sunlight, providing shade without stifling the environment.

Whether used in fiberglass mesh for shading solutions in gardens or as a component of sun-blocking structures, it ensures you can enjoy the outdoors without the harsh sunrays beating down on you. This ability to keep the sun at bay while maintaining a comfortable atmosphere makes fiberglass mesh a versatile and valuable material.

What is the temperature rating for fiberglass mesh?

Fiberglass mesh is like a chameleon when it comes to temperature. It can withstand both extreme cold and scorching heat with ease, making it a dependable choice in a variety of climates and applications.

In applications like fiberglass mesh for concrete countertops, where exposure to extreme temperatures during curing is common, fiberglass mesh remains unfazed. It doesn’t warp, melt, or lose its structural integrity under these conditions. This resilience to temperature fluctuations ensures that your projects stay on track, no matter the weather.

Does fiberglass mesh burn?

Safety is paramount, and fiberglass mesh has your back. It is inherently non-combustible, which means it won’t contribute to the spread of flames in case of a fire. This fire-resistant quality makes it a reliable choice for environments where fire safety is a concern.

Imagine a scenario where fiberglass mesh repair is being carried out near potential fire hazards. Knowing that the mesh won’t ignite or add fuel to the fire provides peace of mind and ensures a safer working environment.

What is the best mesh size?

Selecting the right mesh size is crucial, and it depends on the specific needs of your project. For some applications, a finer mesh is preferred, while others benefit from a coarser weave.

In fiberglass mesh for mosaic tiles, a smaller mesh size provides greater detail and precision. Each piece of the mosaic adheres securely to the mesh, resulting in a stunning finished product. On the other hand, fiberglass mesh for concrete reinforcement benefits from a larger mesh size, offering robust structural support in construction projects.

Why is a smaller mesh better?

A smaller mesh is akin to a tightly woven safety net, offering enhanced strength and durability. It creates more intersections within the fabric, resulting in increased stability.

Consider the scenario of fiberglass mesh for plastering. A smaller mesh size ensures a smoother and more even surface, reducing the chances of cracks or imperfections. This meticulous attention to detail is what sets smaller mesh apart, making it the preferred choice in applications where precision is paramount.

What are the different types of fiberglass mesh fabric?

Fiberglass mesh is a versatile material, and there are several different types of fiberglass mesh, each designed for a specific use based on factors such as weave pattern, weight, and coating. Here are some common types of fiberglass mesh:

This type of fiberglass mesh is treated with an alkali-resistant coating and is usually made of acrylic or latex. It is commonly used in cement-based applications such as stucco and plaster to provide reinforcement and prevent cracking.

This mesh has an adhesive backing that sticks easily to surfaces without the need for additional adhesive. It is often used in drywall and drywall installations to reinforce seams and seams.

Heavy-duty fiberglass mesh has a thicker weave and higher weight, making it suitable for applications requiring extra strength and durability. It is commonly used on roofs, floors and as the base material for mosaic tiles.

This type of fiberglass mesh has a finer weave and is used in applications that require a smoother surface, such as wall repair or as a backing for decorative veneer.

This type of mesh is designed to withstand high temperatures and is often used in industrial applications such as furnace or oven insulation.

This type of mesh is specifically designed for use with window and door screens, providing insect protection while allowing airflow and visibility.

This is a narrow tape of fiberglass mesh with an adhesive backing. It is commonly used to reinforce joints and seams in drywall and other building materials.

The choice of fiberglass mesh depends on the specific requirements of the project, including the type of material used, expected stresses and environmental factors. Different types of fiberglass mesh offer varying levels of strength, flexibility, and resistance to different chemicals and conditions. Therefore, it is important to choose the right type of fiberglass mesh for your specific application.

Is Fiberglass mesh safe?

Safety is a top priority, and fiberglass mesh is a safe material to work with. It is non-toxic, poses no health risks, and is user-friendly. When working with fiberglass mesh for plaster walls, there’s no need to worry about harmful emissions or irritants.

This safety extends to handling and installation as well. Whether you’re a professional contractor or a DIY enthusiast, you can work with fiberglass mesh confidently, knowing it won’t compromise your health or well-being.

What is the density of fiberglass mesh?

The density of fiberglass mesh varies, allowing for customization based on your requirements. A higher density equates to more fiberglass strands per unit area, resulting in increased strength and reinforcement.

Imagine using fiberglass mesh for tiles where high-density mesh ensures that your tiles remain securely in place, even under heavy use. Conversely, in applications like fiberglass grid mesh fabric, where flexibility is key, a lower density provides the necessary pliability.

How strong is Fiberglass mesh?

Strength is the hallmark of fiberglass mesh. Its exceptional tensile strength, combined with resistance to environmental factors, makes it a dependable choice across industries.

Think about fiberglass mesh for roof repair. It endures the harshest weather conditions, safeguarding your property from the elements. Its robustness ensures longevity and peace of mind, knowing that your investments are well-protected.

What are the Advantages of Aiswix Fiberglass Mesh?

As a leading manufacturer in China, Aiswix prioritizes customer satisfaction and offers high-quality fiberglass mesh products that meet and exceed industry standards.

Quality and Consistency

Aiswix’s fiberglass mesh is renowned for its quality and consistent performance, making it the top choice for those who value reliability.

Timely Delivery

Aiswix understands the importance of timely delivery, and its customer-centric approach ensures that clients receive their orders on schedule.

Expert Customer Service

Aiswix works closely with clients to address any issues or challenges, ensuring a seamless experience from inquiry to installation.

Competitive Pricing

Despite its high-quality products and exceptional service, Aiswix maintains competitive pricing, providing excellent value for clients.

In Conclusion

In the world of materials, fiberglass mesh stands out as a versatile and reliable choice. Its wide range of applications, combined with its impressive properties, makes it a go-to option for industries across the board. Whether you’re in construction, manufacturing, or any other field, understanding the potential of quality fiberglass mesh opens doors to innovative solutions and lasting results. As the largest manufacturer in northern China, Aiswix is committed to delivering high-quality products that meet your needs, and we’re proud to contribute to the success of projects worldwide.

If you have further questions or require specific information about fiberglass mesh, don’t hesitate to reach out to us. Aiswix here to provide you with the expertise and support you need to make the most of this remarkable material.