20 Years Of Fiberglass Woven Roving Production Experience

To provide you with reliable quality and innovative product solutions

Choosing The Right Fiberglass Woven Roving For Your Project

Aiswix versatile fiberglass woven roving can meet the needs of your diverse projects, guaranteeing superior performance and cost-effectiveness.

Plain Weave-Fiberglass Woven Roving, providing balanced strength in the warp and weft directions, with good stability and dimensional control, suitable for applications requiring equal strength in both directions, such as general reinforcement, laminates and repairs.

Twill weave-fiberglass woven roving, provides excellent drape and fit, conforms to complex shapes and contours, has higher strength and impact resistance than plain weave, suitable for high strength-to-weight ratio applications, such as shipbuilding, Car parts and wind turbine blades.

Satin Weave-Fiberglass Woven Roving features a more intricate pattern with excellent drape, fit and flexibility.Ideal for applications requiring a smooth surface finish, high strength and light weight, such as aerospace components, high-end sports equipment and decorative laminates.

Find The Best Specification For Your Project

Aiswix fiberglass woven roving are available in a variety of gauges, enabling you to precisely match your project, ensuring optimum performance and meeting your specific needs.

Unique Features And Benefits Of Aiswix Fiberglass Woven Roving

That’s why Aiswix fiberglass woven roving can meet the unique needs of different industries or project target audiences

Fiberglass rovings have excellent tensile strength while keeping the overall weight of the composite structure to a minimum, making Fiberglass woven roving particularly advantageous in applications requiring a lightweight yet strong material.

Fiberglass woven roving are known for their excellent impact resistance. Its interlaced weave structure effectively disperses and absorbs energy, making it highly resilient to sudden shocks or external forces.

Another advantage of fiberglass woven roving is their high resistance to chemicals, a property that makes them suitable for applications requiring exposure to corrosive substances, maintaining structural integrity and extending the life of the composite.

Aiswix advanced manufacturing processes and quality control measures ensure that the composition and structural integrity of each woven roving roll remains consistent, with unparalleled uniformity in fiber distribution and thickness

The precise manufacturing process and optimized fiber distribution of Aiswix Fiberglass woven roving make the woven roving have a smooth surface, minimize the occurrence of fiber print-through, and improve the overall aesthetics and quality of the final product.

Aiswix products are manufactured using a precise and controlled process which ensures that each roll of woven roving contains a high concentration of premium glass fibers which results in superior reinforcement and enhanced mechanical properties.

Experience The Power Of Fiberglass Woven Roving Reinforced Structures

Whether you are using it for shipbuilding, swimming pool manufacturing or other industries such as winding pipe, FRP enhanced, etc., Aiswix is your ideal choice.

Aiswix Fiberglass Woven Roving is widely used in pipe production. It has high strength and uniform weaving, which can ensure the tightness and uniform thickness of the cloth during the winding process and improve the overall quality and stability of the pipe.

Aiswix fiberglass woven roving has high strength, uniform weaving, and good corrosion resistance. It can improve the structural strength of the hull, reduce weight, and has the advantages of design flexibility and easy processing and installation.

Aiswix Fiberglass Woven Roving has excellent properties such as acid and alkali resistance, corrosion resistance, and weather resistance; it can be completely soaked when combined with resin and has a smooth surface; it is widely used in FRP reinforced materials.

Fiberglass Woven Roving is used to enhance the structural integrity of swimming pool surfaces, making them strong and durable, and is often applied with resin to form a composite material that is waterproof and provides excellent strength and stability.

Customization For Your Unique Needs

Aiswix understand that every project and application is unique, and Aiswix bring your vision to life with tailor-made fiberglass mesh solutions.

Product Solutions

For customers who have not yet started to expand their business, Aiswix will provide you with relevant training courses;

For traders, Aiswix will provide you with a complete product solution;

For manufacturers, Aiswix will recommend specifications suitable for your project, provide technical parameters.

Product customization

Aiswix offer a range of product customization options to ensure our products meet your specific needs, including weight per unit area and thickness, width and length, weave patterns, customizable compatibility with different types of resins, special specification customization.

Packaging customization

Whether you need carton packaging, woven packaging, tube packaging, tray packaging or other additional custom packaging (special labels, branding, etc.), Aiswix can make your vision a reality.

Free Sample Test

Aiswix can provide you with free samples for testing, you can accurately evaluate whether our product is suitable for your project needs in your own environment, and Aiswix will make corresponding improvements based on your test feedback.

Ask Your Fiberglass Woven Roving Expert

Help you choose the most suitable and valuable product to complete your project!

Uk Aiswix New Materials Co., Ltd

Uk Aiswix new materials co., ltd is a professional glass fiber enterprise with more than 20 years of experience, committed to providing customers with high-quality fiberglass materials. It mainly produces and sells fiberglass products such as fiberglass roving, fiberglass chopped strand, fiberglass chopped strand mat, fiberglass fabric, etc.

Aiswix has a unique asset base and refined management, enabling us to produce high-quality glass fiber products that meet customer needs.

The Source Of High-End Quality For Aiswix Fiberglass Wowen Roving

1.Raw Material Preparation

The process begins with the preparation of raw materials, which typically include glass fibers, resin, and additives. The glass fibers are usually made from melted glass that is drawn into thin strands or filaments.

2.Twisting Process

In this step, the glass fibers are formed by pulling the molten glass through tiny holes in a platinum bushing. As the glass fibers pass through the bushing, they solidify and form continuous strands.

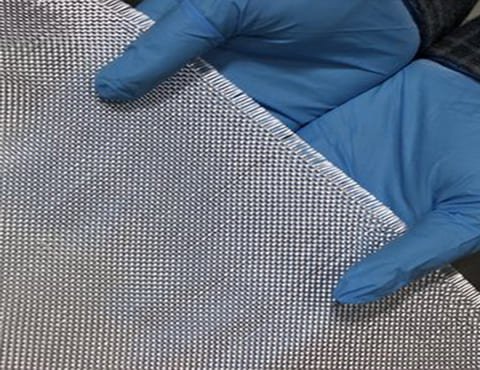

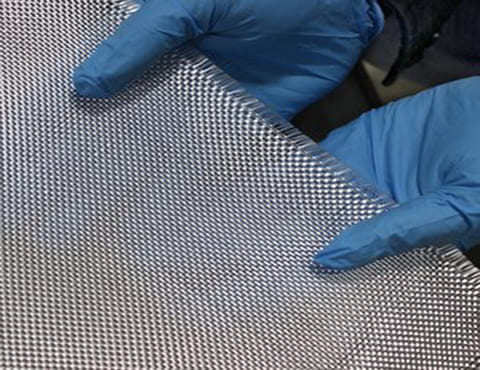

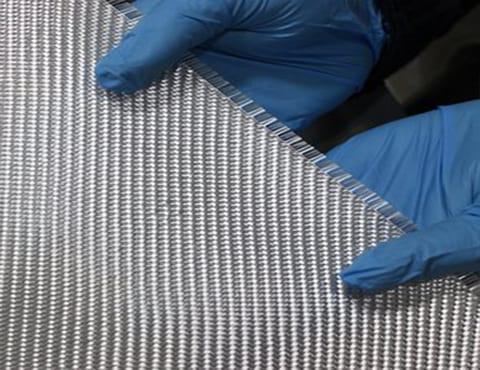

3.Weaving

The lubricated glass fiber is woven into a fabric using a loom. The weaving process interweaves the fibers in a criss-cross pattern to form a stable and uniform weaving structure, which determines the weight of the roving and the specific weaving pattern.

6.Packaging

The final step is the packaging of the fiberglass woven roving, which we usually wrap with protective material and place in strong boxes or trays. Web rolls or sheets are carefully packed to protect the finished product from damage during shipping and storage.

5.Conduct inspections

Aiswix will implement various quality control measures including dimensional checks, tensile strength testing, resin compatibility testing and other relevant assessments to ensure the consistency and highest quality standards of fiberglass woven rovings

4.Cutting Process

Depending on the application or customer’s needs, the dry-laid roving is cut to the desired length or width, and the cut roving is packaged into rolls, rolls or other forms suitable for transportation and storage.

From North America to Europe, from Asia to Africa, and even further afield, Aiswix fiberglass has entered diversified markets

Operating in 126 countries and supplying the highest quality materials to over 1000 customers worldwide, Aiswix value the trust you place in us and are committed to helping you succeed. As part of Aiswix family of satisfied clients, you will receive personalized support and tailored solutions to move your project forward.

Aiswix Standout Performance At The Exhibition

Aiswix establish connections with global industry professionals and explore cooperation to meet the diverse needs of customers from all walks of life.

JEC Composites Show is the leading international trade fair dedicated to the field of composites. The exhibition provides Aiswix with an unparalleled opportunity to showcase Aiswix high-quality, all-round fiberglass product solutions, establish business contacts and expand Aiswix influence in the global fiberglass market.

BIG5 Dubai, the largest construction event in the Middle East, provides an excellent opportunity for networking and business development and collaboration within the construction industry, where Aiswix showcase us high quality and reliable fiberglass mesh for various construction applications cloth ability.

The Canton Fair, also known as the China Import and Export Fair, is one of the largest and most informative trade fairs held in China. Aiswix booth attracted a diverse audience, from potential customers to industry experts and exhibitors, and Aiswix take great pride in the exceptional quality and performance of fiberglass.

The Canton Fair attracts numerous international buyers and exhibitors from different industries. Brings together professionals from the fiberglass and related industries to discuss the latest innovations. Allowing Aiswix to showcase our fiberglass products to a global audience and explore potential partnerships.

JEC Composites Show brings together key players from all over the world, by participating in JEC Composites Show, Aiswix have the opportunity to meet professionals from various industries, network with potential customers, and gain valuable insights into the latest developments and trends in composites.

The BAU Exhibition is one of the world’s leading trade fairs for construction, materials and construction-related systems. At the show we share our knowledge and expertise, highlight Aiswix product quality and commitment to customer satisfaction, and gain valuable insights into emerging trends.

Lasting Impression: Aiswix Fiberglass Customer Visit And Trust Buildin

Experience Aiswix modern factory, professional service and sincere hospitality.

Australia

Building Materials Company

Afghanistan

External Wall Insulation

Middle East

Waterproofing Contractor

United States

Fiberglass Rebar

South African

Trader/Wholesaler

Water Storage Tank

Manufacturers in India

Polish Trader/Wholesaler

Russia Wire And Cable

Factory

Efficient Packaging And Shipping Solutions

Ensuring Protection and Integrity from Production to Delivery

Package

1.40kg/roll 20rolls/tray (normally 1m wide) Net weight: 800kg Gross weight: 825kg

2. Box size: 260*260*1020 Pallet size: 1100mm*1100mm

3. 20-foot container with 20 pallets and 16 tons, 40-foot container with a weight limit of 25 tons

Transportation

Aiswix Fiberglass supports multiple shipping methods (sea shipping, air shipping, rail shipping), Aiswix can recommend the best shipping method for you.

Delivery Detail

15 days after receiving the deposit.

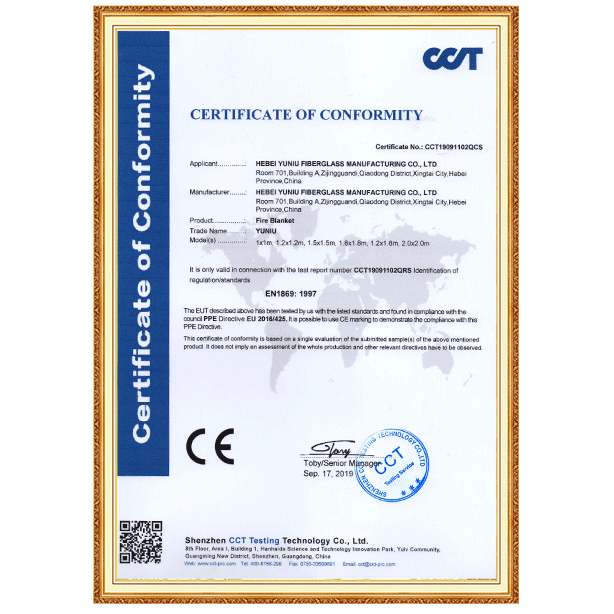

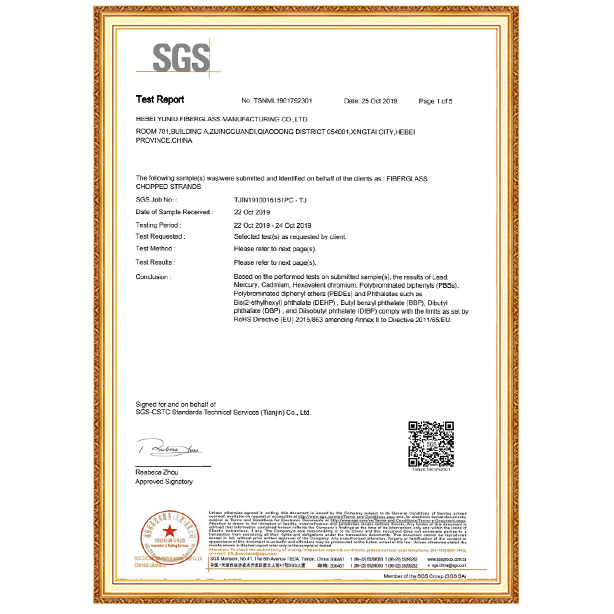

Trusted Certifications For Quality Assurance

You can have full confidence in the quality and compliance of our products, Aiswix give priority to third-party testing, obtain CE, ISO9001, SGS, BV and other certifications to ensure that our products meet global standards.

CE Certificate

The CE certificate is a mark of conformity to European Union regulations. This certification indicates that Aiswix fiberglass comply with the health, safety, and environmental requirements set by the EU. It assures our customers that Aiswix products meet the necessary standards for their intended use in European markets.

SGS Certificate

The SGS certificate is issued by a world-renowned inspection, verification, testing and certification company, which marks that Aiswix fiberglass products have undergone rigorous testing and evaluation, and complies with industry standards and regulations, reflecting Aiswix commitment to high-quality and safe products.

ISO9001 Certification

ISO9001 certification is an internationally recognized quality management system standard. This certification demonstrates that Aiswix company has implemented and maintains effective quality management practices. ISO9001 certification highlights Aiswix focus on customer satisfaction and adherence to strict quality standards.

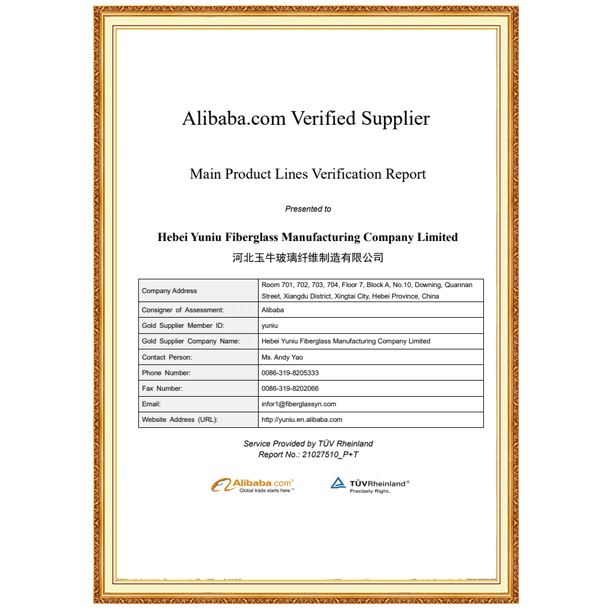

Alibaba Gold Supplier

Aiswix company has obtained the prestigious Alibaba Gold Supplier status, which signifies Aiswix reputation, reliability and long-term commitment to providing quality products and services, and proves Aiswix ability to provide trustworthy and reliable fiberglass to customers around the world product.

Long-Term Partnership And Continued Trust

Find out how some of our customers have found success with Aiswix fiberglass wowen roving

Answer For You

Frequently Asked Questions About Fiberglass Woven Roving

These Q&As are designed to address concerns and doubts that customers may have when considering trading with Aiswix by providing transparent information, timely support.

Yes, our fiberglass woven rovings are uniquely designed for efficient resin penetration resulting in higher saturation and less resin consumption compared to other fiberglass products. This helps to optimize the resin to fiber ratio while maintaining excellent performance and strength in the final composite.

Our fiberglass woven roving does not have inherent defoaming properties as it is primarily used as reinforcement. However, when combined with the proper resin system, this combination can help minimize foam formation during cure.

Our fiberglass woven rovings have excellent tensile strength, providing enhanced structural integrity and durability to the final composite product. What's more, our glass fiber woven rovings provide a cost-effective solution for reinforcing composite materials, allowing you to obtain excellent strength and performance without excessive material expenditure.

We use strong, heavy-duty packaging materials and work with reliable shipping partners who understand the requirements for handling fragile materials. Rest assured, we prioritize the safe delivery of our products to ensure they arrive in perfect condition.

We recommend opting for Western Union, as it offers a more favorable handling fee. However, for new clients, we currently only accept payments through 50% T/T. On the other hand, if you have been a long-standing customer and are experiencing financial constraints, we offer the option of OA credit.

It depends on whether you need to customize, if you don't need to customize, we can ship within 7 days if we have stock, if you don't have stock and need to customize, it will take 7~15 days!

After delivery, you will generally receive the goods in about 45 days, but the specific time you receive the goods depends on your port, shipping date, customs clearance time and other factors.

Technical Support: Our team of experts is ready to help you diagnose and resolve any technical issues or challenges you may encounter;

Customer Support: We can provide product guidance and advice as well as order tracking and delivery updates according to your specific requirements, ensuring a smooth and hassle-free process from purchase to receipt;

PLACE YOUR ORDER TODAY TO AVAIL ALL THESS BENEFITS!

Free samples for testing your project!

50+ fiberglass product catalogue!

Product customization plan!

Problem solved solution!

86-18833998929

infor1@fiberglassyn.com