Introduce

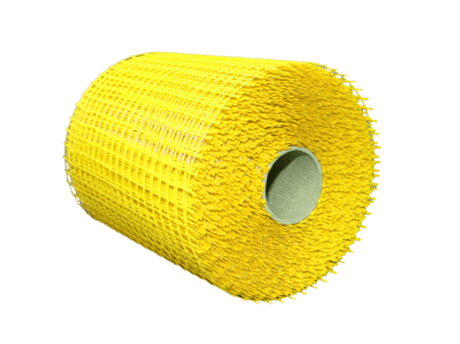

In the realm of construction and industrial applications, fiberglass mesh fabric emerges as a silent powerhouse, contributing to the structural integrity and longevity of diverse projects. This comprehensive exploration delves into the myriad applications and performance attributes that make fiberglass mesh fabric a cornerstone in various industries.

What is fiberglass mesh used for?

Fiberglass mesh is a versatile material employed in various applications across industries. One of its primary uses is in construction. The mesh is often embedded in plaster or stucco to reinforce and provide structural integrity to walls. Its open-weave design allows for better adhesion of plaster, preventing cracks and enhancing the overall durability of the structure.

Additionally, fiber glass mesh finds applications in the manufacturing of composite materials. It is commonly used in the production of fiberglass-reinforced plastic (FRP), which is widely utilized in automotive components, boat hulls, and even aerospace structures due to its lightweight yet robust characteristics. The mesh acts as a reinforcing agent, contributing to the strength and flexibility of the final composite product.

In the realm of arts and crafts, fiberglass mesh roll becomes a valuable tool. Artists often use it as a support structure for sculpting or mold-making, providing a framework for various artistic endeavors. Its malleability and ease of use make it a preferred choice in the creation of intricate shapes and forms.

What is the density of fiberglass mesh?

The density of fiberglass mesh reinforcement can vary depending on the specific product and its intended use. Generally, fiberglass mesh is lightweight, owing to the nature of the material itself. The density is typically measured in grams per square meter (g/m²) or ounces per square yard (oz/yd²).

For construction-grade alkali resistant fiberglass mesh used in wall reinforcement, the density might range from 60 to 160 g/m². This lightweight characteristic is advantageous as it adds minimal additional weight to the construction while still providing excellent reinforcement.

In applications where higher strength is required, such as in certain types of composite manufacturing, the density may be higher, reaching up to 300 g/m² or more. The increased density contributes to enhanced strength and durability of the final composite material.

Is fiberglass mesh waterproof?

Fiberglass mesh itself is not inherently waterproof. However, its properties can contribute to water resistance in certain applications. In construction, when fiber mesh is embedded in plaster or stucco, it forms a protective layer that helps prevent water penetration. The mesh acts as a barrier, reducing the likelihood of cracks and enhancing the overall water resistance of the structure.

In composite materials, fiberglass mesh fabric can be used in conjunction with waterproof resins to create water-resistant or waterproof final products. This is particularly useful in marine applications, where fiberglass-reinforced materials are frequently exposed to water and need to withstand moisture without compromising structural integrity.

It’s important to note that the waterproofing capability often relies on the specific application and the materials used in conjunction with fiberglass mesh.

Is a higher fiberglass mesh count better?

The optimal fiberglass mesh strength count depends on the intended application. A higher mesh count generally means more fibers per square inch, which can result in a finer and more tightly woven mesh. Here’s how the mesh count relates to different applications:

For wall reinforcement in construction, a moderate mesh count is often sufficient. A range of 60 to 80 mesh count is common for these applications, providing a good balance between strength and flexibility.

In industries like aerospace or automotive, where high strength is crucial, a higher mesh count may be preferred. Mesh counts ranging from 100 to 300 or more are common in these applications, ensuring a dense network of fibers for maximum reinforcement.

For artistic purposes, the choice of mesh count depends on the desired level of detail and flexibility. Artists might opt for finer mesh counts (100 or higher) when working on intricate projects that require a smoother surface.

In summary, the “better” mesh count is subjective and contingent on the specific requirements of the project at hand.

Does fiberglass mesh make concrete stronger?

Yes, fiber mesh roll can significantly enhance the strength and durability of concrete when used as a reinforcing material. When embedded in concrete, the mesh provides tensile strength, which is crucial in preventing cracks and improving the overall performance of the concrete structure.

Concrete is strong in compression but weak in tension. By incorporating fiberglass mesh material into the concrete mix or placing it within the layers of concrete, the composite material benefits from the tensile strength of the fiberglass. This helps counteract the tensile forces that can lead to cracking, especially in situations where the concrete is subjected to bending or flexural stress.

The use of fiberglass grid mesh in concrete applications is common in construction projects, including sidewalks, driveways, and even in precast concrete elements. It’s a cost-effective and efficient way to reinforce concrete, resulting in structures that are more resistant to cracking and have increased longevity.

How long does Fibreglass mesh last?

The lifespan of fiberglass grid mesh fabric depends on several factors, including the quality of the mesh, environmental conditions, and the specific application. Generally, fiberglass mesh is known for its durability and long-lasting performance. Here are some considerations:

In plaster and stucco applications, fiberglass mesh can contribute to the longevity of the structure by preventing cracks. When installed correctly, it can endure for decades without significant degradation.

Fiberglass mesh cloth used in composite materials is designed to withstand various environmental conditions. Properly manufactured composites can have a long lifespan, especially when used in applications such as boat hulls or automotive components.

For artistic uses, the longevity of fiberglass mesh net depends on factors like exposure to the elements. Indoor artistic installations or sculptures may last indefinitely, while outdoor pieces may require additional protective coatings to withstand weathering.

It’s essential to follow manufacturer recommendations for installation and maintenance to ensure the optimal lifespan of fiberglass mesh in any application. Regular inspections and necessary repairs or replacements can further extend its longevity.

Customer Praise

In Conclusion

In conclusion, fiberglass mesh is a versatile material with applications ranging from construction to art. Understanding its uses, properties, and appropriate mesh counts can help maximize its benefits in various projects. Whether reinforcing concrete, creating lightweight composites, or adding structural support to artistic creations, fiberglass mesh proves to be a valuable and enduring tool across diverse industries.