Introduce

As a building material with a long history and wide application, concrete is highly favored for its good compressive strength, plasticity and relatively low cost. However, traditional concrete materials have certain limitations in terms of tensile strength and durability. Especially in modern society, with the development of construction technology and the improvement of people’s requirements for living environment, traditional concrete structures can no longer fully meet the growing demand. Therefore, finding new materials and technologies that can improve the performance of concrete has become one of the key research directions.

In recent years, with the continuous advancement of composite material technology, a new type of reinforcement material called glass fiber mesh (Glass Fiber Reinforced Grid, GFRG) has gradually attracted people’s attention. This fiberglass mesh for concrete has shown a wide range of application prospects in the construction industry with its excellent mechanical properties, good chemical stability and low density.

Definition of Fiberglass Mesh

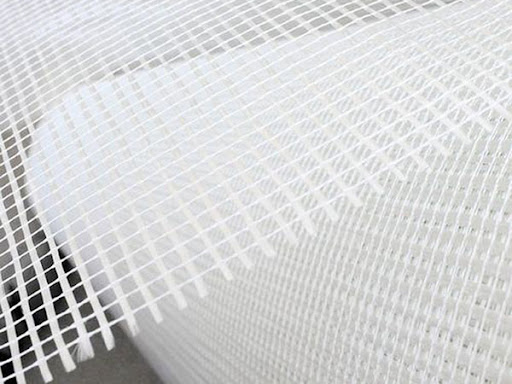

Fiberglass mesh is a multifunctional material mainly composed of glass fiber and polymer resin. Fiberglass is first woven into a loom-state mesh and then impregnated with coatings to create a strong and durable material that strengthens and stiffens the structure and increases the material’s properties to withstand a variety of applications. The combination of these components gives fiberglass mesh roll exceptional strength and flexibility, making it ideal for a wide range of uses.

Characteristics of fiberglass mesh

Physical properties

As an advanced composite material, the physical properties of fiberglass mesh determine its unique advantages in the construction field. Here are some of the main physical properties:

- High strength-to-weight ratio: fiberglass mesh has very high tensile strength, while its density is relatively low. This high fiberglass mesh strength-to-weight ratio allows the fiberglass mesh to maintain its shape even when subjected to large loads. When the fiberglass mesh is embedded in concrete, it can effectively disperse stress, thereby reducing the probability of cracks and increasing the bearing capacity of the entire structure.

- Temperature resistance: Fiberglass mesh has good temperature resistance and can maintain its mechanical properties over a wide temperature range. This means that it can still provide reliable reinforcement even in high or low temperature environments. This is especially important for construction projects located in extreme climates, as the performance of concrete itself can be affected by temperature changes.

- Flexibility and ductility: Although glass fiber itself is relatively hard, its flexibility and ductility are significantly improved after being woven into a mesh. This feature makes the fiberglass mesh easier to handle during construction and can better fit the surface of complex shapes, thereby ensuring a good combination of reinforcement materials and concrete.

- Impact resistance: Fiberglass mesh also exhibits excellent impact resistance. When subjected to external impact or vibration, it can absorb and disperse energy, reduce damage to the concrete structure, and extend the service life of the building.

Chemical properties

Fiberglass mesh not only has excellent physical performance, but also outstanding chemical stability. The following are its main chemical properties:

- Corrosion resistance: The main component of glass fiber is silicon dioxide, which has high chemical stability. Therefore, fiberglass mesh can maintain its structural integrity and is not easy to degrade when facing corrosive substances such as acids, alkalis, and salts. This is crucial for buildings located in areas with severe industrial pollution or coastal areas, where the environment is often highly corrosive.

- Environmental adaptability: In addition to corrosion resistance, fiberglass mesh also has good environmental adaptability. Whether it is a humid or dry environment, it can maintain its original physical properties unaffected. This means that even under changing natural conditions, fiberglass mesh can provide lasting protection for concrete structures.

- UV resistance: Fiberglass mesh has undergone special surface treatment to resist the erosion of ultraviolet rays. When used outdoors, this feature helps prevent material aging and ensures its long-term performance stability.

Processing technology

The production process of fiberglass mesh is also a topic worth discussing, because different production processes will affect the performance of the final product. Here are several key processing steps:

- Fiber preparation: First, high-quality glass needs to be melted and drawn into filaments through a nozzle. This process requires precise control of temperature and drawing speed to ensure the quality and uniformity of the fiber.

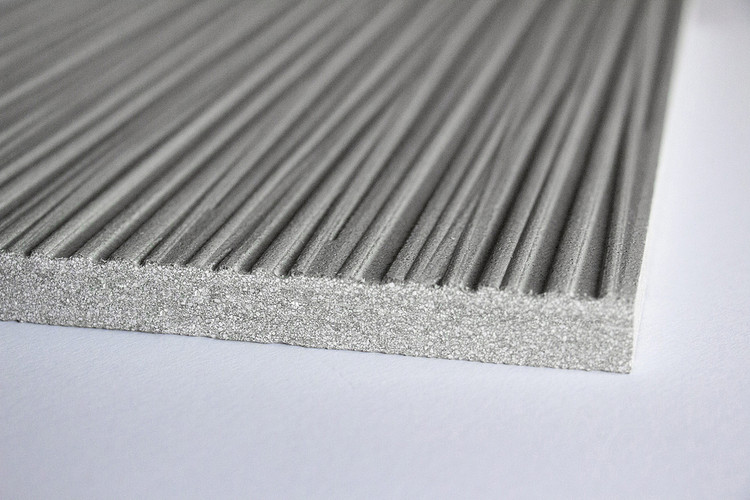

- Weaving: Next, the prepared glass fiber filaments are woven into a mesh according to a specific design pattern. The weaving method can be flat or three-dimensional, depending on the requirements of the end use. The weaving process also requires precise control to ensure the strength and stability of the mesh.

- Post-treatment: Finally, the mesh needs to go through a series of post-treatment steps, such as coating or impregnation with resin, to enhance its bonding with the concrete substrate. These treatments can also give the mesh additional functions, such as waterproofing and UV protection.

Application principle and mechanism analysis

Mechanism of action

- Crack control at the microscopic level: Concrete is prone to microscopic cracks when it is stressed. If these cracks are not controlled, they will gradually expand into macroscopic cracks, thus affecting the safety of the entire structure. The presence of fiberglass mesh can prevent the formation and development of cracks at the microscopic level. When microcracks begin to appear in concrete, the mesh can absorb and disperse the stress around the cracks through its high strength and ductility, thereby inhibiting further expansion of the cracks.

- Enhanced tensile properties: Although concrete materials perform well under compression, they are relatively weak in tension. This is due to the lack of an effective continuous fiber structure within the concrete to transmit tensile stress. When fiberglass mesh is added to concrete, it can form a continuous reinforcing layer inside the concrete, significantly improving the tensile properties of the concrete. This not only increases the overall strength of the concrete structure, but also improves its ability to resist external forces.

- Improve the overall stiffness: The addition of fiberglass mesh can also increase the overall stiffness of the concrete structure. In practical terms, this means that the structure deforms less when subjected to load, thus improving the safety and comfort of the building. In addition, the increase in stiffness also helps reduce the displacement of the structure under wind load or earthquake load, enhancing the seismic performance of the building.

- Improve durability: Since fiberglass mesh has good corrosion resistance, when it is combined with concrete, it can effectively protect the steel bars inside the concrete from corrosion. In addition, mesh cloth can also reduce the chance of moisture and harmful substances penetrating into the interior of the concrete, thereby extending the service life of the concrete structure.

Comparison with other reinforcement materials

- Rebar: Rebar is one of the most traditional concrete reinforcement materials. It has extremely high tensile strength, but it also has some obvious disadvantages. For example, rebar is susceptible to corrosion, especially in humid or saline environments; in addition, it is heavy, which increases the deadweight of the structure. In contrast, fiberglass mesh not only has excellent corrosion resistance, but also is lightweight, which can reduce the burden on the structure.

- Carbon fiber: Carbon fiber is also a high-performance reinforcement material with very high strength and modulus. However, carbon fiber is expensive and may react with alkaline substances in concrete in some cases, affecting its long-term performance. In contrast, fiberglass mesh is more reasonably priced and has better chemical stability and is not easily affected by the chemical environment inside the concrete.

- Polypropylene: Polypropylene fiber is a lightweight synthetic fiber that is often used in concrete to improve its crack resistance. However, the strength and modulus of polypropylene fiber are relatively low and cannot provide the same reinforcement effect as fiberglass mesh. In addition, polypropylene fiber may soften at high temperatures, affecting its long-term performance. Fiberglass mesh exhibits better temperature resistance and can maintain its structural stability over a wider temperature range.

Specific application of glass fiber mesh in concrete

Renovation of old buildings: For old buildings, the original concrete structure may develop cracks or other forms of damage over time. In this case, reinforcing with fiberglass mesh is a cost-effective option. By laying the mesh in the damaged area and pouring a new layer of concrete on it, the cracks can be effectively sealed, restoring or even exceeding the bearing capacity of the original structure. This method is not only simple and quick to construct, but also has less impact on the surrounding environment, making it very suitable for renovation projects in urban central areas.

Application in new construction projects: In new construction projects, fiberglass mesh also plays an important role. By pre-arranging mesh cloth inside concrete components, the bending and shear resistance of the components can be significantly improved, thereby reducing the risk of cracking due to load. In addition, during the manufacturing process of prefabricated parts, the use of fiberglass mesh reinforcement can also improve the integrity and consistency of components and facilitate subsequent assembly operations.

Exterior wall insulation and decoration: In addition to enhancing structural performance, fiberglass mesh is also widely used in exterior wall insulation systems and decorative materials. It can be closely combined with the insulation layer to form a solid protective layer to prevent the insulation material from being damaged by external environmental factors. At the same time, the mesh can also provide a flat base layer for subsequent decoration work such as painting or tiling.

Improve the bearing capacity of the road and bridge deck: For transportation infrastructure such as roads and bridges, their surfaces need to withstand frequent rolling of vehicles and various loads. Glass fiber mesh cloth can be laid under the asphalt layer or in the concrete bridge deck to enhance the overall stiffness of the structure and reduce the damage caused by vehicle loads. In addition, it can effectively disperse the concentrated stress caused by the wheel track effect and prevent premature damage to the road surface.

Application in special sections: In some special sections, such as tunnel entrances and exits, bridgehead slabs and other locations, due to complex foundation conditions, traditional reinforcement methods are difficult to achieve ideal results. At this time, it is particularly necessary to use glass fiber mesh cloth for reinforcement. It can not only adapt to complex terrain changes, but also effectively prevent road cracking caused by foundation settlement.

- In marine environments or saline-alkali areas, concrete structures are extremely susceptible to erosion by seawater or salt. However, fiberglass mesh, due to its non-metallic properties, is not affected by these factors. By applying an appropriate protective coating on its surface, its anti-corrosion ability can be further enhanced, thereby ensuring the stability and durability of concrete structures under these harsh conditions.

- Fiberglass mesh can perform well in both cold northern regions and hot desert areas. Under low temperature conditions, it can still maintain sufficient toughness to prevent cracking caused by temperature changes; while under high temperature conditions, it can effectively resist the effects of thermal expansion and contraction and maintain the integrity of the structure. Therefore, fiberglass mesh is an ideal choice when designing buildings or infrastructure to cope with extreme climatic conditions.

- In areas where earthquakes occur frequently, the seismic performance of buildings is particularly important. Fiberglass mesh can improve its ability to resist earthquake shocks by enhancing the integrity and stability of concrete structures. Especially for old buildings, by adding fiberglass mesh to walls and floors, their seismic resistance level can be significantly improved to protect people’s lives and property.