Introduction

In today’s rapidly developing construction industry, the continuous emergence of new materials has not only promoted the advancement of construction technology, but also greatly enriched the choices of architectural designers. Among them, glass fiber mesh, as a high-performance composite material, has received widespread attention and application in recent years. This paper aims to explore the application and importance of glass fiber mesh in the field of construction, and review the relevant research background.

The basic concept of fiberglass mesh

Fiberglass mesh is a mesh material woven from glass fiber filaments. This material usually has high strength, good weather resistance and chemical stability. The glass fiber itself is a slender fiber made of molten silica (SiO2) and other auxiliary materials (such as calcium, magnesium, and aluminum oxides) through a high-temperature wire drawing process. After special treatment, these fibers can be formed into mesh cloths of various specifications, suitable for different construction needs.

The grid structure of fiberglass mesh not only increases the mechanical strength of the material, but also enables it to better disperse stress when subjected to external forces, thereby effectively preventing the material from cracking. In addition, due to its lightweight characteristics, fiberglass mesh is more convenient during construction, easy to cut and install, and reduces labor costs and construction time.

Importance and research background in the construction industry

With the continuous improvement of society’s requirements for building quality and the increasing attention to sustainable development and energy conservation and emission reduction, the selection of building materials has become one of the key factors affecting building performance. As a new type of reinforcing material, glass fiber mesh cloth has shown great potential in the field of construction due to its excellent physical properties and environmental protection characteristics.

In the building insulation system, glass fiber mesh cloth is widely used as a reinforcing material in the exterior wall insulation layer. It can effectively improve the overall strength of the insulation system and extend its service life. At the same time, this material also plays an important role in waterproofing projects, especially in the fields of underground waterproofing and roof waterproofing. It can enhance the structural stability of the waterproof layer and reduce the risk of cracks caused by environmental changes.

In addition to the above applications, glass fiber mesh cloth also shows unique advantages in building reinforcement, sound insulation barriers and other aspects. With the advancement of science and technology and the growth of market demand, the research on glass fiber mesh cloth is also deepening, and the development of new materials, the optimization of production processes and the expansion of application scope have become the focus of research.

In summary, as a building material with broad application prospects, glass fiber mesh cloth not only improves the safety and comfort of buildings, but also provides strong support for achieving the goal of green buildings. Next, this article will explore the specific applications of glass fiber mesh and the technical advantages it brings from multiple angles, and will also look forward to future development trends.

Fiberglass Mesh Overview

Definition and characteristics

1. Material

Fiberglass mesh is a new type of building material made of alkali-free glass fiber as the main raw material and processed through specific processes. Alkali-free glass fiber, as the name suggests, means that its composition contains almost no alkali metal oxides (such as sodium and potassium), which gives the material better chemical stability and mechanical strength. The manufacturing process of fiberglass involves pulling molten glass through a high-speed rotating spout into fibers with extremely fine diameters, which are then woven or knitted into a mesh-like structure.

2. Grid structure characteristics

The mesh structure of fiberglass mesh is designed to enhance the overall performance of the material. This structure enables the material to have the following significant characteristics:

High strength: The fibers of the mesh are criss-crossed, which can better disperse stress when it is stretched or compressed, thereby improving the tensile strength and compressive strength of the material.

Breathability: Due to the existence of the mesh, the material has a certain degree of breathability, which helps the moisture inside the wall to be discharged and prevents mildew caused by moisture accumulation.

Lightweight: The mesh cloth is light in weight, easy to transport and install, and reduces the difficulty and cost of construction.

3. Chemical properties

Fiberglass mesh has the following excellent chemical properties:

Corrosion resistance: Alkali-free glass fiber is not easily eroded by corrosive substances such as acids and alkalis, so it can maintain a long service life in humid or corrosive environments.

Temperature resistance: Glass fiber has high heat resistance and can maintain its physical properties unchanged over a wide temperature range.

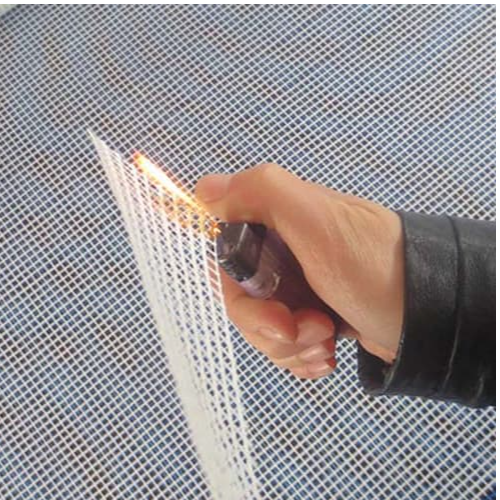

Non-combustible: Glass fiber itself does not burn and does not produce harmful gases even under high temperature conditions, complying with the fire safety requirements of modern buildings.

.png)

Production process

1. Raw material selection

The first step in producing fiberglass mesh is to select the right raw materials. Commonly used raw materials include:

Glass sand: As the main component, the choice of glass sand directly affects the quality of the final product. High-quality glass sand should have a pure and uniform particle size.

Flux: In order to reduce the melting temperature and improve the fluidity of the melt, an appropriate amount of flux, such as borates, will be added during the production process.

Surface treatment agent: In order to improve the bonding strength between fibers and the durability of the material, the fibers will be coated with a layer of surface treatment agent during the production process.

2. Manufacturing process

The manufacturing process of fiberglass mesh mainly includes the following steps:

Melting: The raw materials are melted in a high-temperature furnace, and the temperature is generally above 1400℃.

Wire drawing: The molten glass liquid is drawn into slender glass fibers through a nozzle.

Bundling and weaving: The drawn fibers are bundled according to a certain density and direction, and then woven into a grid shape through a weaving machine.

Coating treatment: In order to improve the performance of the mesh, a layer of special resin or other materials will be coated on its surface to enhance its weather resistance and mechanical strength.

3. Quality Control

During the production process, strict quality control is the key to ensuring product quality. Quality control includes:

Raw material inspection: Strict inspection of incoming raw materials to ensure that they meet production standards.

Online monitoring: Multiple inspection points are set up on the production line to monitor key parameters such as fiber diameter and mesh size in real time.

Finished product testing: The produced mesh cloth is subjected to multiple tests such as tensile strength and weather resistance to ensure that the product meets relevant standards.

Factory inspection: A comprehensive inspection is carried out before the product leaves the factory to ensure that the quality of each batch of products is stable and reliable.

Application

Fiberglass mesh has a wide range of applications in the construction field due to its unique physical and chemical properties. Whether it is exterior wall insulation system or waterproofing engineering, or anti-crack reinforcement and other special uses, fiberglass mesh can play an important role. The following will discuss these application areas separately, with a special emphasis on its role in gypsum board and cement board reinforcement.

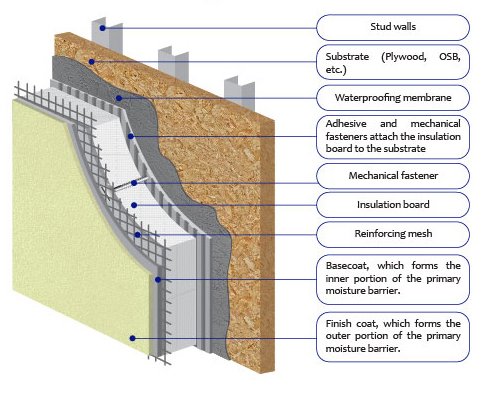

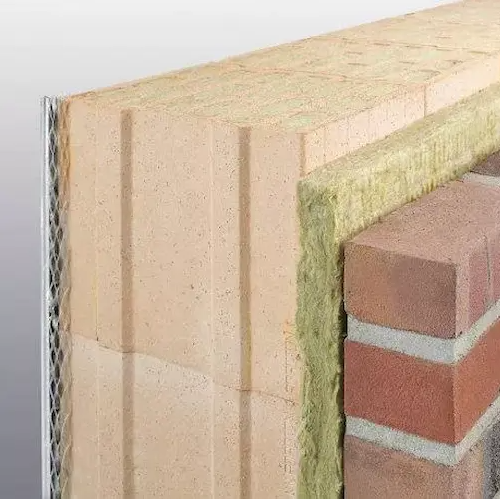

Under the background of building energy conservation, the exterior wall insulation system has gradually become one of the key measures to improve building energy efficiency. As an important component of the exterior wall insulation system, the application of glass fiber mesh cloth is mainly reflected in the following aspects:

1. Enhance the stability of the insulation layer

The exterior wall insulation system is usually composed of insulation materials, bonding layers, mesh cloth reinforcement layers, plaster layers, etc. The glass fiber mesh cloth is located on the insulation layer, and the overall stability of the insulation layer is enhanced through the mesh structure, so that it is not easy to deform or fall off when subjected to external pressure or temperature changes.

2. Improve the crack resistance of the insulation layer

The insulation layer is prone to cracks due to the temperature difference effect, and the glass fiber mesh cloth has good ductility and tensile strength, which can effectively prevent the generation and development of cracks, thereby extending the service life of the insulation system.

3. Assist in achieving building energy conservation goals

The exterior wall insulation system enhanced by using glass fiber mesh cloth can not only improve the thermal insulation effect of the building, reduce energy consumption, but also improve living comfort, which is in line with the design concept of modern building energy conservation.

Waterproofing is an indispensable part of building construction, especially in basements, roofs and other parts. The application of fiberglass mesh in such projects is mainly reflected in:

1. Underground waterproofing

In basement waterproofing, fiberglass mesh can be used as part of the waterproof layer. By combining with waterproof coatings or other waterproof materials, it can enhance the structural strength of the waterproof layer and prevent groundwater from penetrating into the building.

2. Roof waterproofing

For roof waterproofing, fiberglass mesh can also play a role in reinforcing the waterproof layer, especially at the joints or edge areas. By laying mesh, cracking caused by thermal expansion and contraction can be effectively avoided, thereby improving the reliability of the entire roof waterproofing system.

In building construction, anti-crack reinforcement is an important link, especially in infrastructure such as the connection between new and old walls, bridges, and tunnels. The main applications of fiberglass mesh in this area include:

1. Gypsum board reinforcement

Gypsum board is a common interior decoration material, but due to its limited strength, it is prone to cracking when subjected to large external forces. By laying fiberglass mesh on the surface of the gypsum board and covering it with special putty powder, the crack resistance of the gypsum board can be significantly improved and its service life extended.

2. Cement board reinforcement

Although cement board has high strength, there is still a risk of cracking in some cases, especially at the expansion joints of buildings. Fiberglass mesh can be laid on the surface of the cement board or embedded in the cement mortar layer to enhance the overall strength of the cement board and prevent cracks.

3. Infrastructure reinforcement

In the construction of bridges, tunnels and other infrastructure, fiberglass mesh can be used to reinforce concrete structures and improve their durability and load-bearing capacity. Especially when repairing aging infrastructure, the application of mesh can effectively prevent concrete from spalling and extend the service life of the facility.

In addition to the above application areas, fiberglass mesh cloth also plays an important role in many special uses:

1. Noise barrier

On both sides of urban roads or noise-sensitive areas, fiberglass mesh cloth can be used as part of the sound barrier, and combined with sound-absorbing materials to achieve the effect of reducing noise.

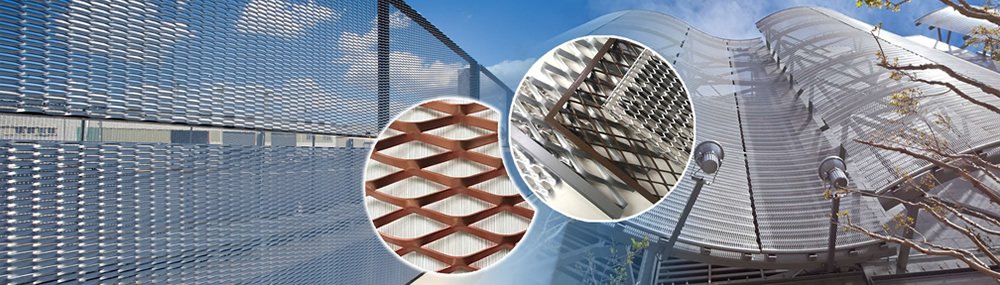

2. Decorative materials

In the field of architectural decoration, fiberglass mesh cloth can also be used as the base layer of decorative materials, which can be beautified by spraying, veneer, etc., which is both beautiful and practical.

3. Special functional materials

With the advancement of science and technology, fiberglass mesh cloth has also been developed into new materials with special functions, such as composite materials with fireproof and moisture-proof functions, which have higher application value in specific occasions.

Technological advantages and market trend analysis

The reason why fiberglass mesh cloth can be widely used in the construction field is inseparable from its unique technical advantages. The following points are its main technical advantages:

1. Convenience of construction

Easy to cut and install: Fiberglass mesh cloth has a soft texture and can be easily cut to the required size and shape according to construction needs, and installation can be completed without complex tools.

Strong adaptability: Whether it is a flat or curved surface, fiberglass mesh can fit well, especially in buildings with complex structures, its flexibility is particularly outstanding.

Reduce construction period: Due to its lightweight characteristics, the use of fiberglass mesh can greatly shorten construction time and improve work efficiency.

2. Economic benefits

Reduce maintenance costs: Due to the excellent weather resistance and anti-aging properties of fiberglass mesh, using this material can significantly reduce maintenance costs in the later stages of the building.

Improve the life of the building: By enhancing the structural stability of the wall, insulation layer and waterproof layer, fiberglass mesh can effectively extend the service life of the building, thereby indirectly bringing economic benefits.

Energy saving: The application of exterior wall insulation systems helps improve the energy efficiency of buildings, reduce energy consumption, and can save a lot of energy expenses in the long run.

3. Environmentally friendly

Recyclable: Fiberglass is a recyclable material, and the waste generated during its production process can be remelted and reused, reducing resource waste.

Low carbon emissions: Compared with traditional building materials, the production process of fiberglass mesh has lower energy consumption and less carbon emissions, which meets the development requirements of green buildings.

Non-toxic and harmless: Glass fiber itself does not contain harmful substances, does not release harmful gases, is harmless to human health, and meets the standards of environmentally friendly building materials.

1. Market Status

In recent years, with the continuous improvement of people’s requirements for building quality and living environment, and the gradual advancement of the country’s energy-saving policies for buildings, the demand for glass fiber mesh has shown a steady growth trend. This is particularly evident in the following aspects:

Residential buildings: With the acceleration of urbanization, a large number of new residential projects have put forward higher requirements for high-quality building materials, and glass fiber mesh has been widely used for its excellent performance.

Public buildings: In public buildings such as schools, hospitals, and office buildings, the application of glass fiber mesh not only improves the safety of buildings, but also enhances their aesthetics.

Infrastructure: In the construction and maintenance of infrastructure such as bridges and tunnels, glass fiber mesh is highly favored for its excellent reinforcement performance.

2. Prospects

In the future, with the advancement of technology and changes in market demand, the application of glass fiber mesh in the construction field will be more extensive, and the following development trends are expected:

Technological innovation: The research and development of new materials will further enhance the performance of glass fiber mesh, such as improving its mechanical properties through nanotechnology to make it more adaptable to extreme environments.

Green and environmental protection: With the enhancement of environmental awareness, the environmental protection requirements for building materials are getting higher and higher. As a green building material, the market share of fiberglass mesh is expected to continue to expand.

Policy support: The government’s emphasis on building energy conservation and green buildings will promote the introduction of relevant policies, which is conducive to the promotion and application of fiberglass mesh.

International market expansion: With the advancement of international cooperation projects such as the “Belt and Road Initiative”, fiberglass mesh is expected to enter more international markets, especially those developing countries and regions with high demand for building materials.

In Conclusion

As a high-performance new building material, fiberglass mesh has shown great application value in the construction field. From exterior wall insulation systems to waterproofing projects, to anti-crack reinforcement and other special uses, fiberglass mesh has brought many technological innovations to the construction industry with its unique physical and chemical properties. This article outlines the basic concepts of fiberglass mesh, discusses its specific applications in the construction field in detail, analyzes its technical advantages and market trends, and fully demonstrates the superiority of fiberglass mesh and its important position in the construction industry through specific case analysis and performance comparison in different application scenarios.

Among the many companies that provide fiberglass mesh, Aiswix, as a company focusing on the production and research and development of high-quality building materials, can provide high-quality products and services to our customers. The fiberglass mesh produced by Aiswix has the following characteristics: high-standard raw materials to ensure the strength and durability of the product. The use of advanced production equipment and technology, strict quality control to ensure that the product meets international standards. At the same time, customized products can be provided according to customer needs to meet the special requirements of different application scenarios. Aiswix is not only committed to providing high-quality fiberglass mesh, but also continuously conducting technological research and development to launch new products that meet market demand. Through cooperation with many well-known construction companies and scientific research institutions at home and abroad, Aiswix has accumulated rich practical experience and continues to promote the innovative application of fiberglass mesh in the field of construction.