Introduce

In the realm of construction materials, EIFS (Exterior Insulation and Finish System) distinguishes itself through its blend of aesthetic appeal and functional efficiency.Our commitment to quality and reliability has attracted a diverse clientele of manufacturers, traders, and engineering businesses who value the consistency and dependability of our products. Clients like Hans, a seasoned R&D manager from an American company, trust us for solutions that meet their precise needs. This article explores the critical role of eifs fiberglass mesh in ensuring the longevity and performance of EIFS systems, highlighting where quality meets innovation.

What Is EIFS?

To truly appreciate the role of eifs fiberglass mesh, it’s essential to understand that EIFS is a multi-layered wall system providing both insulation and decorative finishes. It consists of a base coat over a substrate, insulation boards, a reinforcing mesh embedded in a second base coat layer, and a finish coat for the final appearance. EIFS excels in offering superior thermal insulation, crucial for energy efficiency, with its effectiveness heavily reliant on high-quality components, especially the reinforcing mesh. The eifs fiberglass mesh acts as the backbone, ensuring all layers bond securely, even under challenging conditions. This mesh is vital not only for insulation but also for maintaining the sleek, modern look and design versatility of EIFS, transforming building appearances while catering to various architectural styles.

Different Types of Fiber Mesh

Fiberglass mesh fabric is widely used in various industries due to its excellent quality:

Beyond Fiberglass: Exploring Other Options

While eifs fiberglass mesh remains the dominant choice for EIFS applications, other types of fiber mesh exist and serve various purposes in the construction industry. Carbon fiber mesh, for instance, is known for its exceptional tensile strength and lightweight properties, making it suitable for specialized applications requiring high-performance characteristics.

Insulation

Whether you are insulating the interior or exterior of a building, this fiberglass mesh materials plays a vital role in reinforcing the insulation, helping to maintain temperature control, energy efficiency, and structural integrity.

Waterproofing

Fiberglass mesh waterproofing is a popular choice for preventing water intrusion on roofs and other construction projects, creating a waterproof barrier that prevents moisture from penetrating and causing damage.

Restoration

Auto enthusiasts and professionals use fiberglass mesh to effectively repair car bodies.

Seam Cracks

Whether it is marble backing, drywall installation, fiberglass mesh can provide strength and prevent seam cracks for the perfect result in your finish.

What are the Characteristics of Fiberglass Mesh?

Quality fiberglass mesh boasts several key characteristics:

High Strength

Fiberglass mesh is known for its exceptional tensile strength, making it a reliable choice for reinforcement purposes.

Flexibility

It offers flexibility without compromising its durability, allowing it to adapt to different shapes and surfaces.

Corrosion Resistance

Fiberglass mesh is resistant to corrosion, ensuring long-term performance even in harsh environments.

Lightweight

Despite its strength, glass fiber mesh is lightweight, making it easy to handle and install.

Is a Higher Fiberglass Mesh Count Better?

In general, a higher fiberglass mesh count means a finer weave and a smoother surface. However, the choice of mesh count depends on your specific application. A higher count is often preferred for projects that require a smoother finish, such as mosaic tile work, while coarser meshes are suitable for applications like concrete reinforcement.

What are the Different Types of Fiberglass Mesh?

Fiberglass mesh is a versatile material, and there are several different types of fiberglass mesh, each designed for a specific use based on factors such as weave pattern, weight, and coating. Here are some common types of fiberglass mesh:

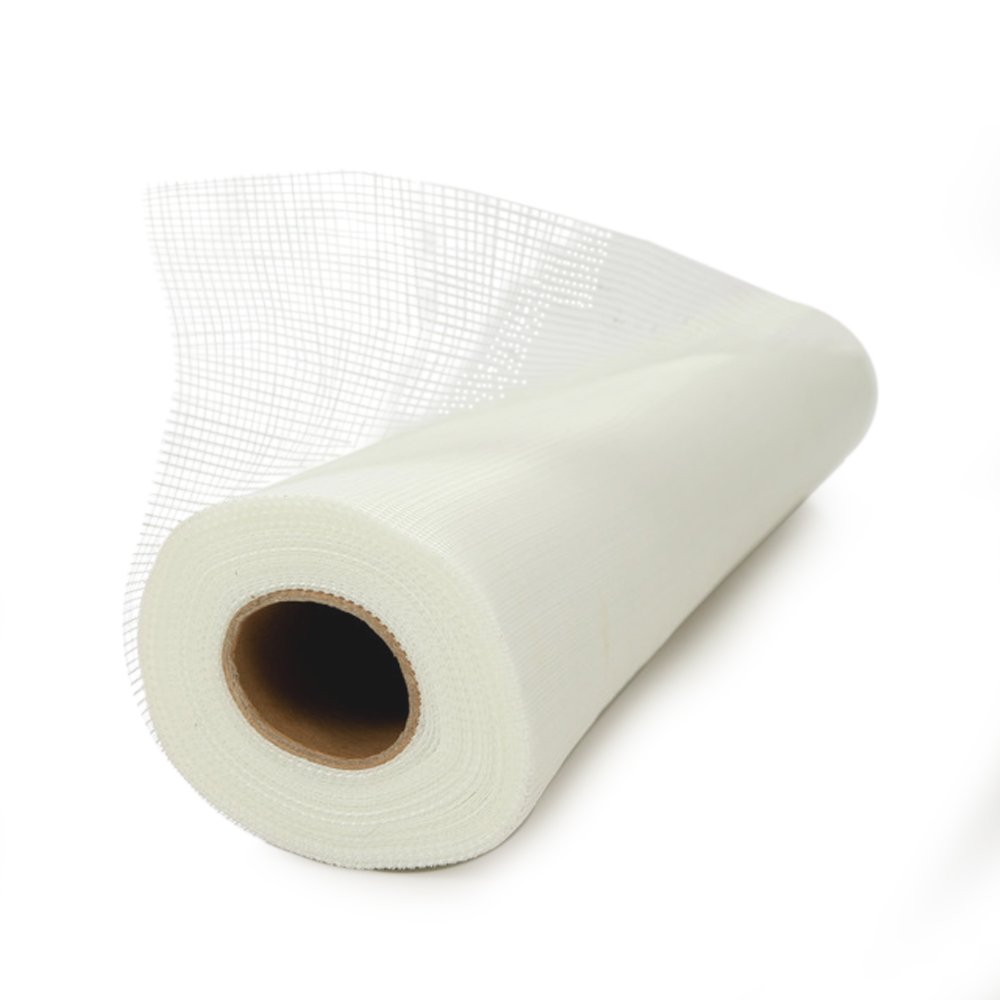

This type of fiberglass mesh is treated with an alkali-resistant coating and is usually made of acrylic or latex. It is commonly used in cement-based applications such as stucco and plaster to provide reinforcement and prevent cracking.

This mesh has an adhesive backing that sticks easily to surfaces without the need for additional adhesive. It is often used in drywall and drywall installations to reinforce seams and seams.

Heavy-duty fiberglass mesh has a thicker weave and higher weight, making it suitable for applications requiring extra strength and durability. It is commonly used on roofs, floors and as the base material for mosaic tiles.

This type of fiberglass mesh has a finer weave and is used in applications that require a smoother surface, such as wall repair or as a backing for decorative veneer.

This type of mesh is designed to withstand high temperatures and is often used in industrial applications such as furnace or oven insulation.

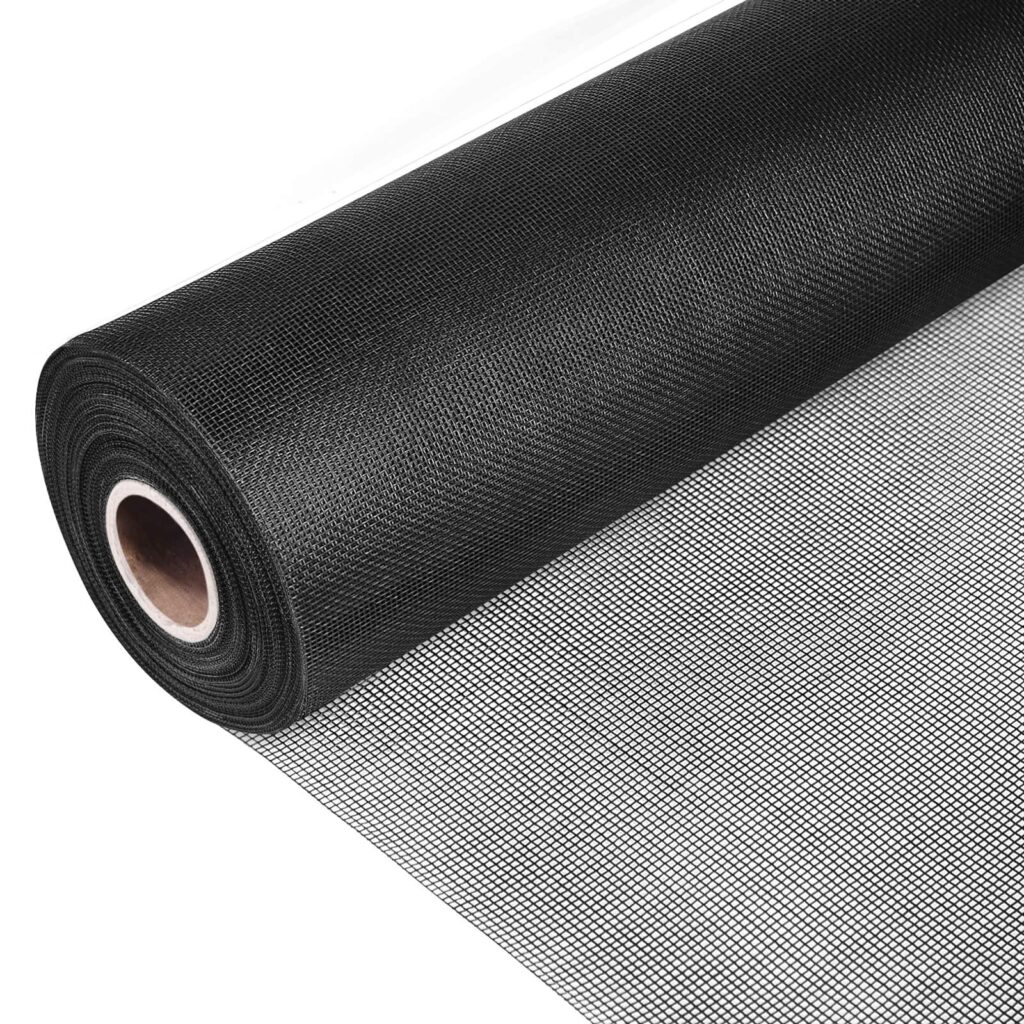

This type of mesh is specifically designed for use with window and door screens, providing insect protection while allowing airflow and visibility.

This is a narrow tape of fiberglass mesh with an adhesive backing. It is commonly used to reinforce joints and seams in drywall and other building materials.

The choice of fiberglass mesh depends on the specific requirements of the project, including the type of material used, expected stresses and environmental factors. Different types of fiberglass mesh offer varying levels of strength, flexibility, and resistance to different chemicals and conditions. Therefore, it is important to choose the right type of fiberglass mesh for your specific application.

How Do I Choose the Right Mesh?

Choosing the right fiberglass mesh materials involves considering factors like mesh count, weight, and the specific requirements of your project. Aiswix, with over 20 years of experience in the textile industry, can provide expert guidance to ensure you make the best choice for your application.

How Do You Install Fiberglass Mesh?

Proper installation is crucial for the effectiveness of fiberglass mesh. It typically involves cleaning and preparing the surface, applying adhesive, embedding the mesh, and finishing with a topcoat or adhesive. Aiswix offers not only high-quality fiberglass mesh but also installation support to ensure your project’s success.

How Long Does Fiberglass Mesh Last?

Fiberglass mesh roll is known for its durability and long lifespan. When installed correctly, it can last for decades, even in challenging environments. Its resistance to corrosion and environmental factors makes it a reliable choice for long-term projects.

What are the Advantages of Aiswix Fiberglass Mesh?

As a leading manufacturer in China, Aiswix prioritizes customer satisfaction and offers high-quality fiberglass mesh products that meet and exceed industry standards.

Quality and Consistency

Aiswix’s fiberglass mesh is renowned for its quality and consistent performance, making it the top choice for those who value reliability.

Timely Delivery

Aiswix understands the importance of timely delivery, and its customer-centric approach ensures that clients receive their orders on schedule.

Expert Customer Service

Aiswix works closely with clients to address any issues or challenges, ensuring a seamless experience from inquiry to installation.

Competitive Pricing

Despite its high-quality products and exceptional service, Aiswix maintains competitive pricing, providing excellent value for clients.

In Conclusion

In conclusion, fiberglass mesh is a versatile and dependable material used in various industries for reinforcement, waterproofing, and more. Aiswix, with its commitment to quality, reliability, and customer satisfaction, is a trusted partner for businesses worldwide. Whether you’re in need of fiberglass mesh for concrete reinforcement, mosaic tiles, or any other application, Aiswix has you covered.

Are you ready to explore the world of fiberglass mesh and discover how it can benefit your projects? Contact Aiswix today, and let us be your partner in quality and reliability!