Introduce

With the continuous advancement of industrialization and the rapid development of technology, the development and application of new materials have become one of the key factors in promoting the progress of modern industry. Among them, glass fiber, as an important inorganic non-metallic material, has shown its unique advantages in many fields. Glass fiber is a fibrous material made by drawing natural mineral raw materials such as quartz sand, limestone, dolomite, etc. after high-temperature melting. It has many advantages such as light weight, high strength, corrosion resistance, and high temperature resistance. Therefore, it is widely used in construction, automobiles, aerospace, electronics and other industries. Especially today, with increasingly stringent environmental protection requirements, glass fiber has become an ideal substitute for many traditional materials with its excellent performance. Among these many product forms, glass fiber needle felt has gradually become a popular new material due to its unique structure and excellent performance.

Fiberglass needle mat material is made by dry non-woven process. It is formed by repeated puncture of loose glass fibers through fine needles on the needle machine to form a three-dimensional mesh structure. This special processing method not only gives the product good flexibility and air permeability, but also ensures its high strength and durability. Due to its unique structural characteristics, glass fiber needle felt has found a wide range of applications in multiple industries, from industrial filtration to thermal insulation to electrical insulation. This article will introduce in detail the characteristics of glass fiber needle felt and its specific applications in different fields, so as to better understand and utilize the unique advantages of this material.

The basic concept of glass fiber needle felt

Fiberglass mesh fabric is widely used in various industries due to its excellent quality:

Definition

Glass fiber needle felt is a material made of glass fiber through a non-woven process. It usually adopts dry non-woven technology, and the loose glass fibers are processed through multiple processes to finally form a three-dimensional mesh structure with certain strength and stability. The main component of this material is glass fiber, but an appropriate amount of adhesive or other functional additives can also be added according to different application requirements. The thickness of glass fiber needle felt can be adjusted according to actual needs, and the common thickness ranges from a few millimeters to tens of millimeters.

During the production process of glass fiber needle felt, the staggered arrangement of fibers forms countless tiny pores, which make the material have good air permeability and sound absorption. In addition, due to the mutual locking effect between fibers, the material as a whole shows high strength and stability, and can maintain good performance in a variety of environments.

Manufacturing Process

The manufacturing process of glass fiber needle felt mainly includes the following steps:

1. Raw material preparation: First, high-quality glass fibers need to be prepared. These fibers are usually made by drawing molten glass through a nozzle, and then cooling and solidifying to form long and thin fibers. In order to meet the needs of different applications, some functional materials such as flame retardants and antistatic agents are sometimes added during the drawing process.

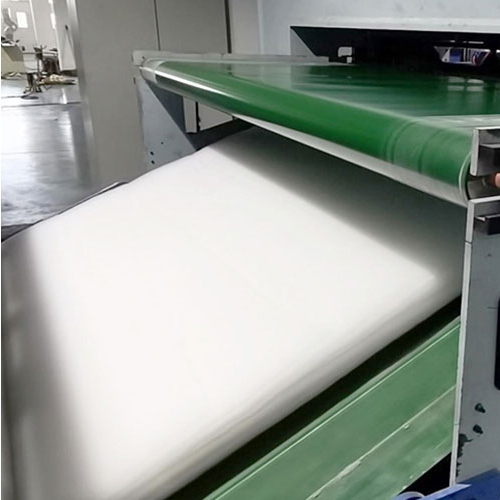

2. Fiber combing: The prepared glass fibers are fed into a combing machine, which makes the fibers more uniform and straight, and removes impurities from the fibers. The combed fibers are laid into layers of fiber webs to prepare for subsequent processing.

Needle punching reinforcement: This is the most critical step. The combed fiber web is fed into a needle punching machine, and the fiber web is repeatedly punctured by a large number of fine needles. These needles have many sharp hooks, which hook the fibers together when they pass through the fiber web, forming a three-dimensional interwoven structure. This process can be repeated many times to ensure that the material has sufficient strength and stability.

3. Post-processing: The material after needle punching reinforcement also needs to undergo certain post-processing to improve its performance. For example, the dimensional stability of the material can be improved by heat setting; or a layer of adhesive can be sprayed on to increase the durability and strength of the material. For some special uses, surface coating can also be performed to give the material more functional properties.

4. Quality inspection and finished product packaging: Finally, the finished glass fiber needle felt is strictly inspected for quality to ensure that all indicators meet the standards. Qualified products will be cut into the required specifications and packaged for transportation and storage.

Characteristics of fiberglass need mat

Physical properties

Fiberglass needle felt has the following significant physical properties:

1. Density: The density of fiberglass needle felt is low, usually between 0.08 and 0.2 g/cubic centimeter. This makes it lighter than traditional metal materials, making it easier to handle and install.

2. Fiberglass needle mat strength: Although its density is low, its strength is high. The three-dimensional structure formed by the needling process gives the material good tensile and compressive strength in all directions.

3. Temperature resistance: Glass fiber itself has excellent temperature resistance and can be used for a long time at temperatures up to 600°C without significant physical changes. This characteristic allows the fiberglass needle felt to maintain good performance in high temperature environments.

4. Stretch resistance: Due to the interaction between fibers, glass fiber needle felt can maintain high strength and is not easy to break when stretched by external forces.

5. Air permeability: Due to the large number of microporous structures inside the material, glass fiber needle felt has good air permeability and is suitable for applications requiring gas exchange.

6. Sound absorption: The microporous structure also gives the material good sound absorption properties, which can effectively absorb noise and reduce environmental noise levels.

7. Dimensional stability: Through post-processing methods such as heating and shaping, glass fiber needle felt can maintain stable dimensions in a wide temperature range and is not easily deformed.

Chemical properties

1. Corrosion resistance: Glass fiber itself has strong resistance to most acid and alkali solutions and is not easily corroded. This feature enables glass fiber needle felt to be used for a long time in harsh chemical environments.

2. Chemical stability: In addition to corrosion resistance, glass fiber needle felt also has good chemical stability, is not easy to react with other substances, and can maintain its integrity in complex chemical environments.

3. Aging resistance: Glass fiber needle felt is not easy to age and has a long service life. Even if it is exposed to natural conditions such as sunlight and moisture for a long time, it can maintain its original performance.

4. Anti-ultraviolet: Glass fiber material has good resistance to ultraviolet rays and is not easily degraded or deteriorated by ultraviolet rays.

Mechanical properties

1. Flexibility: Despite its high strength, glass fiber needle felt has good flexibility due to the interlaced structure of the fibers, is easy to bend and shape, and is suitable for various complex shaped parts.

2. Wear resistance: After the surface of the material is treated, it has good wear resistance, can resist wear and extend the service life.

3. Tear resistance: The mutual locking effect between the fibers makes the material not easy to break when torn, and has high tear resistance.

4. Impact resistance: The three-dimensional structure enables the material to disperse stress when it is impacted, reducing the possibility of local damage.

5. Fatigue strength: Glass fiber needle felt can still maintain high fatigue strength under cyclic loading conditions, and is suitable for applications that need to withstand cyclic loads.

Application of fiberglass needle mat

1. Industrial filtration

Dust collection system: Glass fiber needle felt is often used in industrial dust collection systems as a high-efficiency filter medium. Its high porosity and large surface area enable it to effectively capture particulate matter in the air and maintain air quality. Especially in high temperature, high humidity or corrosive environments, the temperature resistance and corrosion resistance of glass fiber needle felt make it an ideal filter material.

Waste gas purification device: In the process of waste gas treatment, glass fiber needle felt can be used to remove harmful gases and particulate pollutants. It can withstand high temperatures and chemical erosion while maintaining good filtration efficiency, and is suitable for chemical plants, power stations and other industrial facilities.

Liquid filtration: In addition to air filtration, glass fiber needle felt can also be used for liquid filtration, especially in applications that require high temperature resistance and corrosion resistance, such as the pharmaceutical, food processing and water treatment industries.

2. Thermal insulation

Building materials: Glass fiber needle felt is widely used as a thermal insulation material in the construction field due to its excellent thermal insulation properties. It can be laid under walls, roofs and floors to effectively block heat transfer and improve the energy efficiency of buildings.

Industrial equipment: In the industrial field, glass fiber needle felt can be used for thermal insulation of various high-temperature equipment, such as boilers, kilns, pipelines, etc. It not only prevents heat loss, but also protects operators from high temperature damage.

Transportation: In transportation vehicles such as cars, trains and airplanes, it is also used for Fiberglass needle mat heat insulation and sound insulation, improving riding comfort and reducing energy consumption.

Electrical insulation

Cable coating: Glass fiber needle felt has good electrical insulation properties and is often used as an outer covering material for cables. It not only prevents current leakage, but also provides additional mechanical protection.

Electrical equipment protection: In high-voltage electrical equipment, glass fiber needle felt can be used as an insulating gasket or lining to prevent electrical short circuits and leakage accidents.

Transformer insulation: In power transformers, glass fiber needle felt can be used as an insulating material to protect internal components from external interference and ensure the safe operation of the equipment.

3. Composite material reinforcement

Aerospace: In the field of aerospace, glass fiber needle felt is used as a reinforcing material to improve the strength and rigidity of composite materials. It is widely used in the manufacture of high-performance components such as aircraft structural parts and rocket shells.

Automobile Manufacturing: In the automobile manufacturing industry, glass fiber needle felt is used to strengthen the body structure, reduce vehicle weight, and improve fuel economy and safety.

Sports Equipment: Glass fiber needle felt is also used to make high-performance sports equipment, such as skis, golf clubs, etc., to improve product durability and performance.

Market Status and Future Development Trends

1. Stricter environmental regulations: The global attention to environmental protection is increasing, and countries have introduced stricter environmental regulations. This has prompted various industries to seek more environmentally friendly materials and solutions, and glass fiber needle felt is favored for its good environmental performance.

2. Industrial upgrading and transformation: With the deepening of industrialization, more and more traditional industries have begun to transform towards high-tech and high value-added. Glass fiber needle felt has found new application areas in many emerging industries due to its excellent performance, such as new energy vehicles and high-end equipment manufacturing.

3. Infrastructure construction: Large-scale infrastructure construction projects around the world have provided a broad market space for glass fiber needle felt. Whether it is road and bridge construction or urban rail transit, a large amount of thermal insulation and electrical insulation materials are required.

4. Consumption upgrade: As people’s living standards improve, consumers have higher and higher requirements for product quality and safety. Glass fiber needle felt is increasingly widely used in household appliances, home decoration, etc. due to its excellent performance and reliability.

1. New material research and development: Researchers are working on developing higher performance glass fiber materials, such as high strength, high temperature resistance, ultra-fine fiber, etc. These new materials will further broaden the application scope of fiberglass needle felt.

2. Production process optimization: Improve production efficiency and product quality by improving the production process. For example, the use of advanced technologies such as automated production lines and intelligent control can significantly improve the accuracy and stability of the production process.

3. Surface modification technology: By surface modification treatment of glass fiber needle felt, it can be given more functionality, such as waterproof, oil-proof, flame retardant and other properties, to meet the needs of different application scenarios.

4. Application of nanotechnology: The application of nanotechnology brings new possibilities to glass fiber needle felt. By depositing nanoscale materials on the fiber surface, the mechanical, thermal and chemical properties of the material can be improved, making it more competitive.

1. Sustainable development: As society attaches more importance to sustainable development, glass fiber needle felt, as a recyclable and low-emission material, will be more widely used. In the future, more innovative technologies may be applied to its production and application to further improve its environmental performance.

2. Cross-border integration: Glass fiber needle felt is expected to achieve cross-border integration with other materials and technologies to develop more innovative products. For example, combined with smart sensor technology, thermal insulation materials with self-monitoring functions can be manufactured to enhance the user experience.

3. Customized services: As customer needs diversify, glass fiber needle felt manufacturers will provide more customized services to meet the specific needs of different users. This will promote the personalized design and production of materials and improve market competitiveness.

4. International cooperation: In the context of globalization, cross-border cooperation will become an important way to promote the technological advancement and market expansion of glass fiber needle felt. Through international exchanges and cooperation, advanced technology and management experience can be introduced to promote the overall development of the industry.

In Conclusion

This article briefly introduces the basic concepts and manufacturing process of glass fiber needle felt, and also deeply explores its many advantages in physical, chemical, mechanical properties and environmental friendliness. As a high-performance non-woven material, glass fiber needle felt has shown broad application prospects in many fields such as industrial filtration, thermal insulation, electrical insulation and composite material reinforcement due to its light weight, high strength, high temperature resistance, corrosion resistance, and good thermal insulation, insulation and filtration performance. Its excellent performance not only meets the needs of current industrial development, but also conforms to the trend of environmental protection and sustainable development.

The importance and future development potential of glass fiber needle felt cannot be ignored. With the continuous advancement of technology and the growth of market demand, fiberglass needle mat manufactures can gradually expanding its application range, especially in emerging fields such as new energy, high-end manufacturing and environmental protection technology. Its recyclability and low emission characteristics make it a green and environmentally friendly material, which helps to reduce dependence on natural resources and promote the green development of the industry. In the future, with the further development of materials science, glass fiber needle felt will be able to achieve technological innovation and application breakthroughs in more fields, bringing more high-performance and high-reliability solutions to all walks of life.