Introduce

As an advanced manufacturing method, filament winding construction technology is attracting increasing attention in today’s engineering field. Not only does it improve the strength and durability of structures, it also enables the fabrication of complex shapes and designs. In this article, we will explore the definition, background, and importance and application prospects of filament-wound construction in various fields.

Filament Winding

Definition and background of filament wound construction

Filament winding construction is a manufacturing technology that combines fiber materials, such as fiberglass, carbon fiber, etc., with resin or other adhesives, and then wraps them around a mold or structural surface to form the desired shape and structure. This method typically uses automated machines or robots to control the fiber winding process to ensure precise and efficient manufacturing.

Filament winding construction technology originated in the aerospace field in the 1960s and was initially used to manufacture structural components of aircraft such as aircraft and missiles. With the continuous development of material science and manufacturing technology, fiber-wound construction is gradually used in automobiles, ships, construction, sports equipment and other fields. Its unique manufacturing method makes complex structures and lightweight designs possible, revolutionizing the field of engineering.

The importance and application areas of filament winding technology

Fiber winding technology plays an important role and is widely used in the engineering field. First, it can improve the strength and stiffness of the manufacturing structure, making the product more durable and safe. By selecting fibers of different types and directions, the mechanical properties of manufactured parts can be adjusted to meet different engineering needs.

Secondly, filament winding technology enables the manufacturing of complex shapes and designs. Compared with traditional manufacturing methods, it can more flexibly adjust the shape and size of the structure to meet the designer’s requirements for product appearance and functionality. This provides the possibility for innovative design and customized production, promoting the development of the engineering field.

Fiber winding technology has a wide range of applications in various fields. In the aerospace sector, it is used to manufacture aircraft fuselages, engine components and structural parts for spacecraft. In the automotive industry, it can make lightweight bodies and frames, improving fuel efficiency and performance of cars. In the construction field, it can manufacture long-span structures and complex-shaped buildings, enhancing the building’s earthquake and wind resistance. In addition, filament winding technology is also used in fields such as shipbuilding, sports equipment, and wind power generation, providing innovative solutions for various engineering projects.

Fiber Winding Process

The existing fiber winding processes are divided into core mold fiber winding, coreless fiber winding and space fiber winding.

Core Mold Filament Winding

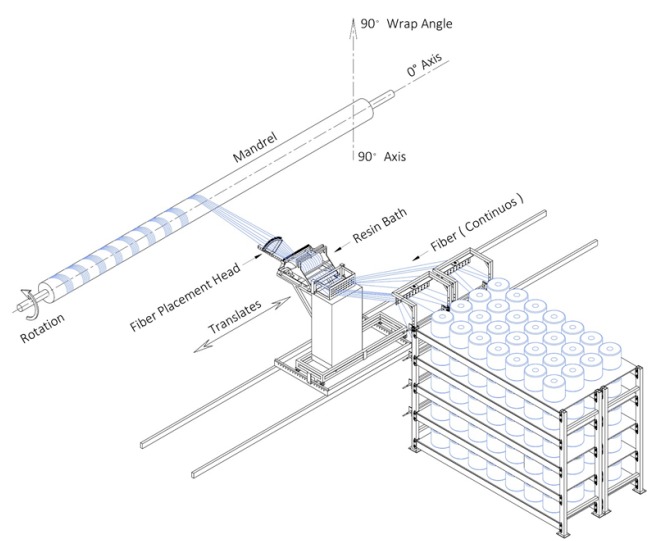

Filament Winding (FW) can be divided into traditional fiber winding and robotic fiber winding. In the traditional fiber winding process, after the fiber bundle passes through the resin bathtub, the speed of the conveyor and the rotation speed of the mandrel are controlled to pull the impregnated fiber bundle so that it is wound around the mandrel at different angles. The fibers solidify under appropriate time and temperature conditions to form a filament-wound product.

Coreless Filament Winding

Coreless Filament Winding (CFW) was first jointly developed in 2012 by the Institute for Computational Design (ICD) and the Institute for Building Structures and Structural Design (ITKE) at the University of Stuttgart, combining engineering methods and computer design. This novel robotic filament winding technology is a construction method that does not require mandrels and typically uses custom steel frames (or scaffolding) as supports, with anchor points placed on these steel frames (or scaffolding) according to the design requirements of the structure. .

During the construction process, the robot end effector pulls the resin-impregnated fiber filaments, and then continuously performs fiber winding actions around the frame according to the established fiber winding grammar and robot motion planning path; the fiber material moves with the robot end effector at the two anchor points. Move back and forth and span freely, and form winding nodes at the anchor points; after repeatedly stacking and laying fiber layers layer by layer, a structure with a multi-layer fiber shell is finally formed; the frame is removed after the impregnated fibers solidify (or scaffolding) to complete the manufacturing of fiber wound components.

Space Fiber Winding

Coreless fiber winding is based on winding fibers around the anchor points of a prefabricated frame, using the anchor points as winding nodes, while Spatial Filament Winding (SFW) is based on coreless fiber winding and adds fibers in the Entanglement in space. Space fiber winding wraps one fiber around another fiber, so that the entanglement between fibers forms nodes.

Coreless fiber winding realizes the construction of components through layered fiber winding, but the interaction of each fiber is limited to the surface contact between each fiber. Space fiber winding expands the concept of winding nodes. By winding each fiber to create winding nodes with multi-fiber interaction, it further reduces the dependence on the frame, so that large-span components with multiple spatial winding points can be created.

Application Prospects

The wide application of filament winding construction technology is constantly expanding the possibilities in various fields, bringing new development opportunities to industries such as construction, aerospace, automobiles, and energy.

In the field of construction, fiber winding construction technology is widely used in structural reinforcement, decoration, new building materials, etc., bringing new solutions to the construction industry.

Structural reinforcement: Fiber winding construction technology can be used to strengthen concrete structures, steel structures, etc., improve the seismic performance and structural strength of buildings, extend service life, and reduce maintenance costs.

Decoration: Using fiber winding construction technology, architectural decorations with diverse and personalized designs, such as railings, columns, vases, etc., can be produced to add beauty and artistry to the building.

New building materials: Fiber winding construction technology can also be used to produce new building materials, such as glass fiber reinforced concrete, carbon fiber composite materials, etc., which have the advantages of light weight, high strength, corrosion resistance, etc., providing more choices for building design and construction.

In addition to the construction field, fiber winding construction technology has also been widely used in other fields, such as aerospace, automobiles, energy, etc.

Aerospace: Fiber winding construction technology is widely used in the aerospace field to manufacture aircraft fuselages, rocket shells and other components. It can reduce structural weight, improve flight performance, and has good fatigue resistance and high temperature resistance.

Automobile: The automobile manufacturing industry is also an important application field of filament winding construction technology. It is used to manufacture body parts, wheels, suspensions and other components, which can achieve lightweight design and improve the fuel economy and driving performance of automobiles.

Energy: In the energy field, filament winding construction technology can be applied to the manufacturing of new energy equipment such as wind power blades and solar photovoltaic panels to improve the efficiency and reliability of energy equipment and promote the development and utilization of clean energy.

Challenges And Prospects

As an innovative technology, filament winding construction also faces some challenges and limitations during its application.

Technical challenges faced by filament-wound construction

Although filament-wound construction technology offers many advantages, there are still some technical challenges that need to be overcome in practical applications.

Automated production: At present, fiber winding construction still relies on a lot of manual operations, and the production efficiency is low. Therefore, how to realize automated production of filament winding construction and improve production efficiency is an urgent technical problem that needs to be solved.

Complex structure manufacturing: Filament winding construction technology has been relatively mature in manufacturing simple structures, but it still faces certain challenges when manufacturing complex structures, such as how to deal with complex fiber laminations, gaps inside the structure, etc.

Material performance control: The material properties of filament winding construction have an important impact on the quality and performance of the final product. How to control the fiber arrangement density, directionality, and parameters such as temperature and pressure during the resin curing process are currently issues that require in-depth research.

Environmental Sustainability and Resource Utilization Considerations

As people pay more and more attention to environmental protection, filament winding construction technology also needs to consider its environmental sustainability and resource utilization efficiency.

Energy consumption: The filament winding construction process requires a large amount of energy consumption, such as electricity, heat, etc. Therefore, how to reduce energy consumption and improve energy utilization efficiency is one of the current environmental issues that need to be solved.

Material recycling: How to deal with the waste materials generated during the filament winding construction process, and how to realize material recycling and resource recycling is one of the current environmental issues that need to be focused on.

Production emission control: Certain waste gas, waste water and other emissions may be produced during the filament winding construction process. How to control and reduce production emissions and reduce the impact on the environment is one of the current environmental issues that need to be solved.

Standardization and standardization requirements for filament winding construction

In order to promote the further development and application of filament winding construction technology, it is crucial to establish relevant standardization and standardization systems.

Technical standardization: Formulating technical standards for filament winding construction, including standards for production processes, material requirements, product quality, etc., will help standardize industry development and improve product quality and technical levels.

Safety standardization: Formulating safety specifications for filament winding construction, including regulations on safe operations during the production process and the safety of production equipment, will help ensure the safety of production personnel and equipment.

Environmental standardization: Formulating environmental specifications for filament winding construction, including regulations on environmental protection measures and waste disposal during the production process, will help reduce pollution and damage to the environment.

In Conclusion

As an innovative technology with great potential, filament winding construction technology has shown broad application prospects and has shown remarkable achievements in many fields. However, its development still faces some challenges and limitations. In the future, we need to continue to explore innovation, strengthen cooperation, and promote the further development of filament winding construction technology.

Prospects and potential of filament winding construction technology

Fiber winding construction technology has broad application prospects and huge potential, which is mainly reflected in the following aspects:

Efficient energy consumption: Filament winding construction technology has high production efficiency and energy utilization efficiency, which can significantly reduce production costs and energy consumption, helping to improve the competitiveness and profitability of enterprises.

Lightweight design: Filament winding construction technology can achieve lightweight design of complex structures, making the product higher strength and stiffness, while reducing the weight of the structure itself, helping to improve the performance and service life of the product.

Material diversity: Filament winding construction technology can be manufactured using various types of fiber materials and resin materials, which can meet the needs of different products and has high flexibility and applicability.

Wide range of applications: Filament winding construction technology has broad application prospects in aerospace, automobile manufacturing, construction engineering, sports equipment and other fields, and can bring more advanced and high-quality products and solutions to various industries.

Future development directions and suggestions

Although filament winding construction technology has achieved a series of achievements, it still needs to continue to explore and innovate, strengthen cooperation, and promote further development of technology in future development. Specifically, we can make suggestions from the following aspects:

Strengthen scientific research strength: Increase scientific research investment in filament winding construction technology, conduct more basic research and applied research, and improve technical level and innovation capabilities.

Expand application fields: Actively explore the application of filament winding construction technology in emerging fields, such as medical equipment, new energy and other fields, and open up new market space.

Strengthen cooperation between industry, academia, and research: Strengthen cooperation between industry, academia, and government departments, establish an innovation system that combines industry, academia, and research, and promote the transformation and application of technology.

Develop specifications and standards: Establish a complete specification and standard system for fiber winding construction technology, strengthen supervision of the production process and product quality, and ensure product safety and reliability.

Through the implementation of the above suggestions, it is believed that filament winding construction technology will achieve more brilliant achievements in the future and make greater contributions to promoting the sustainable development of the economy and society.