Introduce

For over 20 years, Aiswix has pioneered the development of high-performance Fiberglass Self-Adhesive Tape,Self-Stick Fiberglass Tape represents more than just a quick fix—it’s a scientifically engineered solution that bridges the gap between temporary patches and permanent repairs. From oil pipeline maintenance to aerospace component protection, our Fiberglass Repair Tape has become the trusted choice for manufacturers, traders, and engineering firms across 50+ countries.

How Strong is Fiberglass Tape?

At Aiswix, we’ve engineered our Self-Stick Fiberglass Tape to deliver structural-grade performance that challenges traditional metal repairs. Here’s why engineers worldwide trust our solution for critical applications:

Tensile Strength

42-58 N/cm² (ASTM D882 certified) Equivalent to 2mm carbon steel plate at just 20% of the

weight,40% stronger than standard fiberglass tapes on the market

Peel Adhesion: 3.8-4.5 N/mm *(EN 1464 certified)* Maintains bond integrity even under vibration and angular stress,Superior to most industrial epoxy adhesives

Temperature Resistance

-54°C to 204°C continuous service ,Withstands refinery-level heat without degradation.

What is Fiberglass Tape Used For?

Fiberglass tape is a versatile material used in various industries and applications due to its strength, durability, and resistance to heat, chemicals, and moisture. Here are its primary uses:

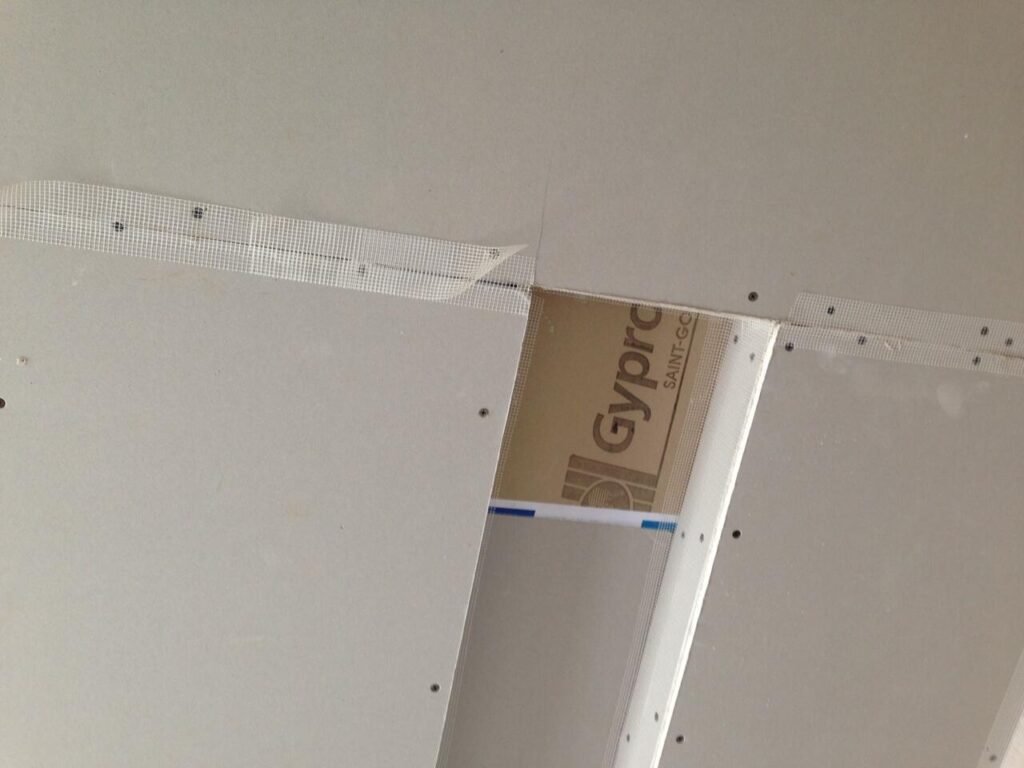

Construction & Home Improvement

Drywall and Plaster Repair: It is commonly used to reinforce and seal joints between drywall panels, preventing cracks and ensuring a smooth surface. The mesh design provides stability for filling compounds.

Wall and Ceiling Patching: Ideal for repairing small holes, cracks, or damaged areas in walls by providing a strong base for joint compound.

Tile Installation: Can be used to secure tiles or as a reinforcing layer in thin-set mortar for added strength in floors or walls.

Industrial & Mechanical Applications

Pipe and Duct Insulation: Wraps around insulated pipes or ducts to hold thermal insulation (e.g., fiberglass or foam) in place, especially in high-temperature environments like HVAC systems.

Corrosion Protection: In industrial settings, it may be used with coatings to protect metal pipes or structures from rust and chemical exposure.

Cable and Wire Management: Secures cables, wires, or hoses to prevent movement or damage, often in machinery or electrical setups.

Automotive & Marine

Vehicle Repairs: Reinforces bodywork, repairs cracks in fiberglass car parts (e.g., bumpers, boat hulls), or serves as a temporary fix for structural issues.

Sealing and Bonding: Used in marine applications to seal joints or repair fiberglass surfaces on boats, thanks to its water resistance.

Electrical & Electronics

Insulation and Protection: Provides electrical insulation for wires or components, especially in high-temperature environments where standard tapes might fail.

PCB Mounting: Secures printed circuit boards (PCBs) in devices or enclosures, offering vibration resistance.

Why Doesn’t My Self-Adhesive Tape Stick?

Common adhesion failures stem from:

Surface Contamination

Oil residues >0.5mg/cm² will compromise bond strength

Temperature Mismatch

Applying below 10°C without pre-heating reduces tack by 60-70%

Substrate Incompatibility

Standard tapes fail on LDPE/PP surfaces without specialty primers

Pressure Deficits

Insufficient roller pressure leaves >15% void areas

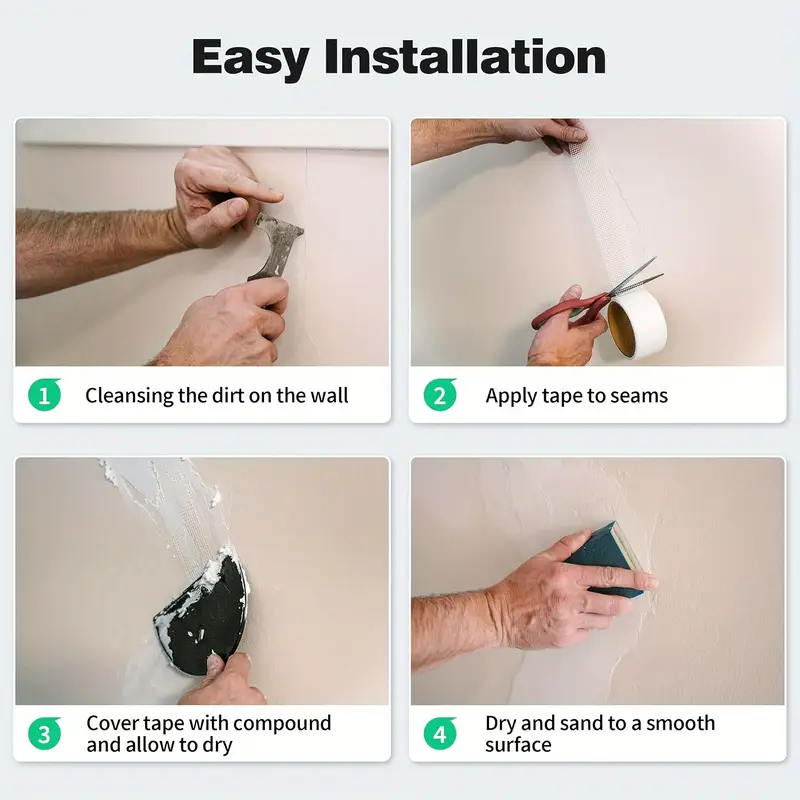

How to Make the Tape Stick Better?

Industrial-Grade Application Protocol:

- SSPC-SP1 solvent cleaning for oil/grease removal

- 50-75μm anchor profile via grit blasting

- Preheat substrate to 15-40°C using IR lamps

- Store tape at 21±3°C for 24h pre-application

- Apply with 10-15kg roller pressure

- Maintain 50% overlap on spiral wraps

- Post-heat to 60°C for 2 minutes (activates adhesive)

- 72-hour cure at 25°C before pressure testing

- Avoid UV exposure during initial cure

Aiswix Fiberglass Self-Adhesive Tape Unparalleled Advantages

At Aiswix, we don’t just make tapes, we engineer solutions to solve your toughest repair challenges. Here’s what makes us different:

Precision Manufacturing Excellence

Smart Coating System: AI-driven applicator maintains ±1.5% adhesive thickness consistency across all Fiberglass Self-Adhesive Tape batches

Certified Quality System: Triple certified to ISO 9001:2015, API 15S, and DNVGL-OS-C50 standards

Complete Process Control: From E-glass fiber formulation to precision die-cutting, we oversee all production stages to ensure quality

Designed for Extreme Performance

Polar Series: Maintains 4.2N/mm peel strength at -54°C

Subsea Solutions: 300+ cycle pressure tested at 300bar (equivalent to 3,000m depth)

Chemical Defense Formula: Proven to resist: 98% H2SO4 @ 60°C for 500 Hours, 15% NaCl salt spray @ 35°C for 1,000 hours, JP-8 jet fuel immersion for 30 days

In Conclusion

Self-adhesive fiberglass tape has evolved from a simple maintenance tool to an engineered solution to multi-billion dollar industry challenges. With tensile strength comparable to steel and chemical resistance exceeding that of most polymers, Aiswix’s Self-adhesive fiberglass tape represents the pinnacle of repair material technology. As a Self-adhesive fiberglass tape manufacturer with two decades of innovation, we invite you to experience the Aiswix difference and contact our technical team today to request a sample kit of our industrial-grade fiberglass repair tape or to discuss the specific requirements of your project.