Introduce

When it comes to high-temperature resistance and insulation, the world of materials offers a plethora of options. From traditional choices like ceramic to more innovative solutions like aerogels, the competition is fierce. However, one material stands out for its exceptional performance and versatility – Fiberglass Needle Mat. As a leading Fiberglass Needle Mat manufacturer and supplier, my company, Aiswix, has been at the forefront of providing this remarkable material to a wide range of industries. In this comprehensive guide, we will explore the top 10 key advantages of Fiberglass Needle Mat as the ultimate high-temperature resistant material.

What is the Best and Most Durable Insulation Material?

When it comes to insulation materials, durability and effectiveness are top priorities. The best insulation material is one that not only provides exceptional thermal protection but also stands the test of time. In this regard, needle mat emerges as a clear frontrunner.

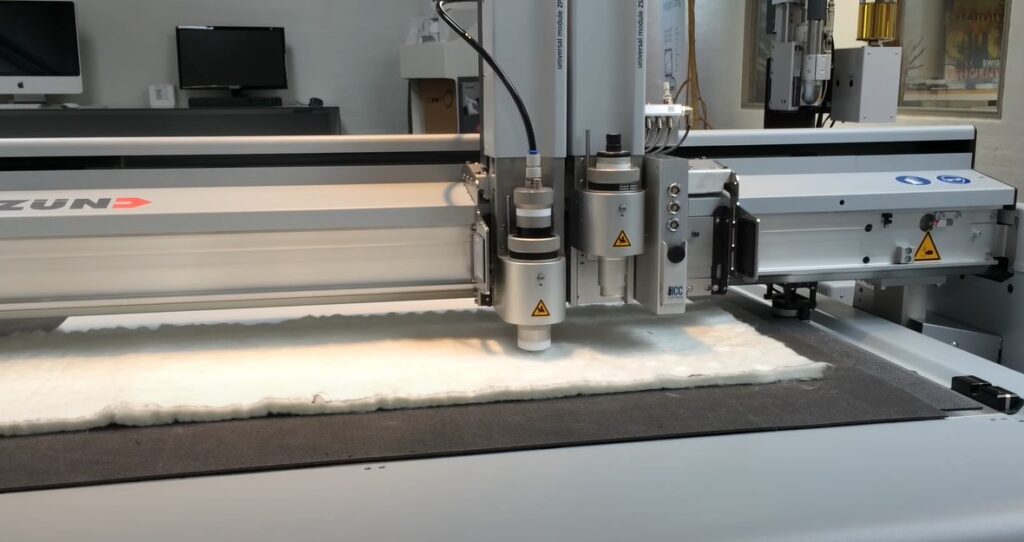

Fiberglass Needle Mat is engineered to be one of the most durable insulation materials available today. Its longevity is a result of a unique manufacturing process that mechanically interlocks fine glass fibers into a robust, three-dimensional structure. This structure is not only incredibly resilient but also resistant to wear and tear, making it an ideal choice for a wide range of applications.

What sets Fiberglass Needle Mat apart is its ability to maintain its insulation properties even under harsh conditions. Whether it’s exposed to extreme temperatures, humidity, or mechanical stress, this material remains steadfast in its performance. This means that once installed, you can count on Fiberglass Needle Mat to provide consistent thermal insulation for years to come.

The durability of High Silica Fiberglass Needle Mat is particularly advantageous in industries where insulation is subjected to frequent maintenance or replacement, as it minimizes downtime and associated costs. Whether it’s insulating industrial equipment, pipelines, or building structures, this insulation material ensures long-term efficiency, making it a cost-effective choice in the long run.

What is the Best Insulation for Hot Climates?

Hot climates present unique challenges when it comes to insulation. In such environments, the best insulation should not only provide effective thermal protection but also be capable of withstanding the relentless heat. Fiberglass Needle Mat proves to be an exceptional choice for hot climates.

Fiberglass Needle Mat’s heat resistance properties shine when temperatures soar. It acts as a barrier against the transfer of heat, preventing it from infiltrating your living or working spaces. This results in a significant reduction in indoor temperatures, ensuring a comfortable and energy-efficient environment even in scorching conditions.

One of the key advantages of High Temperature Insulation Silica Fiber Needle Felt for hot climates is its lightweight nature. Unlike some heavy insulation materials that can trap heat, Fiberglass Needle Mat remains lightweight, making it easier to install and minimizing the load on structures. This is particularly beneficial for construction projects in regions with hot climates.

Moreover, the material’s resistance to moisture and mold growth ensures that it remains effective even in humid, tropical environments. This combination of heat resistance, moisture resistance, and durability makes Pipe insulation Needle felt an ideal choice for hot climates, whether it’s for residential, commercial, or industrial applications.

Is Fiberglass Insulation Mold Proof?

Mold growth can be a serious concern in areas with high humidity or moisture. When it comes to insulation materials, it’s essential to choose one that is resistant to mold growth. fiberglass Needle felt, while not inherently mold-proof, is highly resistant to mold under normal conditions.

The composition of Fiberglass Needle Mat doesn’t provide a favorable environment for mold to thrive. Mold typically requires organic materials and moisture to grow, and insulation needle felt lacks the organic components that mold feeds on. This inherent resistance to mold growth ensures that your insulation remains clean and effective, even in areas prone to high humidity.

Additionally, Fiberglass Needle Mat’s resistance to moisture infiltration further contributes to mold prevention. By blocking the transfer of moisture, it reduces the conditions conducive to mold growth. This makes it a reliable choice for insulation in areas where mold is a potential concern.

It’s important to note that while Fiberglass Needle Mat is highly resistant to mold, proper installation and maintenance are still essential to ensure optimal performance and prevent any potential mold issues. Regular inspections and addressing any sources of moisture are key to keeping your insulation mold-free.

Does Fiberglass Insulation Need a Vapor Barrier?

Vapor barriers are essential components of insulation systems, especially in areas where moisture control is crucial. The good news is that needle mat can be effectively paired with vapor barriers to enhance its moisture resistance and overall insulation performance.

Vapor barriers are materials or coatings that control the movement of moisture vapor, preventing it from penetrating the insulation and reaching the underlying structures. They are particularly important in climates with significant temperature variations, where condensation can occur within walls or ceilings.

Fiberglass Needle Mat‘s compatibility with vapor barriers makes it a versatile choice for various insulation applications. When combined with a vapor barrier, it creates a robust defense against moisture infiltration, ensuring that your insulation remains efficient in maintaining temperature and preventing issues like corrosion or mold growth.

Whether you’re insulating a residential attic, an industrial facility, or a commercial building, the addition of a vapor barrier enhances the overall performance of silica needle mat, making it a reliable choice for moisture control in diverse environments.

Is Fiberglass Insulation Ruined if It Gets Wet?

Water and insulation typically don’t mix well, and wet insulation can lead to performance degradation. However, High Silica Fiberglass Needle Mat is designed to withstand exposure to moisture without being ruined.

Fiberglass Needle Mat’s resistance to moisture is a result of its composition and manufacturing process. Unlike some insulation materials that absorb water like a sponge, Fiberglass Needle Mat repels moisture. It doesn’t readily absorb water, which means it can maintain its insulation properties even when exposed to wet conditions.

This resilience is particularly beneficial in applications where moisture is a concern, such as pipe insulation or construction in rainy climates. Wet conditions, whether from rain or humidity, won’t lead to the deterioration of High Temperature Insulation Silica Fiber Needle Felt, ensuring that it remains effective in providing thermal insulation.

However, it’s essential to note that while Needle Mat can withstand exposure to moisture, proper installation and addressing the source of moisture are critical to ensuring long-term insulation performance. Additionally, prompt drying or replacement may be necessary in cases of extensive water infiltration to prevent potential issues like mold growth.

What is High Temperature Fiberglass Material?

High-temperature environments demand insulation materials that can withstand extreme heat without compromising their integrity. In this context, high-temperature fiberglass materials, such as Fiberglass Needle Mat, are designed to excel.

Fiberglass Needle Mat is engineered to thrive in high-temperature settings. It boasts a remarkable melting point of approximately 1650°C (3000°F), far surpassing the temperatures encountered in most industrial and aerospace applications. This extraordinary heat resistance makes it an invaluable asset in industries where exposure to extreme temperatures is a constant challenge.

In applications like furnace insulation, exhaust systems, and fire protection, where temperatures can reach searing heights, high-temperature fiberglass materials like Pipe Insulation Needle felt ensure that critical components remain protected and operational. Their ability to withstand extreme heat without deforming or degrading is a testament to their exceptional performance.

Furthermore, high-temperature fiberglass materials are known for their low thermal conductivity, which means they effectively block the transfer of heat. This property enhances their insulation capabilities, making them ideal for maintaining temperature control in extreme environments.

Is Fiberglass Insulation Heat Resistant?

Absolutely! Fiberglass insulation, including Fiberglass Needle Mat, is renowned for its heat-resistant properties. This insulation material excels in applications where temperature control and heat resistance are of utmost importance.

The heat resistance of Fiberglass Needle Mat stems from its unique composition and structure. It consists of fine glass fibers that are mechanically interlocked into a three-dimensional matrix. This structure acts as a formidable barrier against the transfer of heat, ensuring that it remains on the outside, keeping interiors cool and safe.

What makes Fiberglass Needle Mat especially appealing is its ability to maintain its heat resistance properties over time. It doesn’t degrade or become less effective with exposure to high temperatures, ensuring consistent performance throughout its lifespan. This reliability is essential in critical applications where temperature stability is non-negotiable.

Moreover, fiberglass needle felt‘s resistance to fire further underscores its suitability for heat-resistant insulation. It is inherently fire-resistant, meaning it doesn’t contribute to the spread of flames or emit harmful smoke when exposed to fire. This fire safety aspect makes it a top choice for industries where fire protection is paramount, such as construction and aerospace.

Are There Different Types of Fiberglass Insulation?

Yes, there are different types of fiberglass insulation, and they serve various purposes depending on the application and specific requirements. One of the notable types of fiberglass insulation is Fiberglass Needle Mat.

Fiberglass Needle Mat stands out due to its unique manufacturing process, which involves mechanically interlocking fine glass fibers into a random, three-dimensional structure. This structure enhances its thermal and mechanical properties, making it suitable for a wide range of applications, including industrial insulation, construction, and aerospace.

Another common type of fiberglass insulation is fiberglass batt insulation, which consists of pre-cut panels or rolls of fiberglass material. These are often used in residential and commercial construction for insulating walls, ceilings, and floors. While effective, they may not offer the same level of versatility and heat resistance as Fiberglass Needle Mat.

Additionally, there are fiberglass loose-fill insulation and spray foam insulation, both of which are suitable for specific applications. Fiberglass loose-fill is often used to insulate attics and hard-to-reach spaces, while spray foam insulation provides an airtight seal and is ideal for sealing gaps and cracks.

The choice of fiberglass insulation type depends on factors such as the application, desired R-value (thermal resistance), and environmental conditions. insulation needle felt, with its exceptional heat resistance and durability, is an excellent choice for applications that require superior thermal protection.

Which Class of Insulation Can Withstand the Highest Temperature?

When it comes to insulation materials that can withstand the highest temperatures, high-temperature fiberglass materials like Fiberglass Needle Mat belong to a class of their own. These materials are engineered to excel in extreme heat and maintain their structural integrity and insulation properties under the most demanding conditions.

While the specific temperature limits can vary depending on the manufacturer and product type, high-temperature fiberglass materials are capable of withstanding temperatures well beyond what many other insulation materials can endure. This makes them indispensable in industries where exposure to extreme heat is a constant challenge.

For instance, in applications like furnace lining, where temperatures can reach thousands of degrees Celsius, or in the aerospace industry, where rockets and spacecraft encounter extreme heat during launch and re-entry, high-temperature fiberglass materials like needle mat are the preferred choice. They provide the critical insulation needed to protect equipment and ensure safe and efficient operations.

Does Fiberglass Expand and Contract with Temperature?

Temperature fluctuations can have a significant impact on many materials, causing them to expand and contract. However, silica needle mat exhibits minimal expansion and contraction with changes in temperature, making it a reliable choice for insulation in diverse environments.

The limited thermal expansion and contraction of Fiberglass Needle Mat are attributed to its unique composition and interlocking structure. Unlike some materials that may expand significantly when exposed to heat or contract in cold temperatures, Fiberglass Needle Mat remains relatively stable.

This stability is a valuable attribute in applications where precise fits or consistent insulation performance are required. For example, in industrial settings where pipes and equipment experience temperature variations, Fiberglass Needle Mat‘s ability to maintain its dimensions ensures that it continues to provide effective thermal insulation.

Furthermore, the minimal expansion and contraction contribute to the material’s longevity. It reduces the risk of gaps or shifts in the insulation, ensuring that it remains in place and functional over time.

In Conclusion

In conclusion, High Silica Fiberglass Needle Mat is an exceptional insulation material that excels in various aspects, including durability, heat resistance, mold resistance, moisture control, and stability in temperature fluctuations. Its unique properties make it an attractive choice for a wide range of applications, from industrial insulation to residential and commercial construction. As a versatile and reliable insulation material, Pipe Insulation Needle felt continues to be the top choice for those seeking superior thermal protection and long-term performance.