Introduce

In today’s competitive materials market, chopped strand mat, as a versatile and high-performance material, is gradually gaining favor in more and more industries. However, for many potential users, the true value of chopped strand mat may not be completely clear. This article will help you gain a deeper understanding of the unique advantages of chopped strand mat and its potential in multiple application fields by answering seven key questions, thereby stimulating your purchasing interest.

Why choose fiberglass chopped strand mat instead of other materials?

The reason why fiberglass chopped strand mat has become the preferred material for many industries is mainly because of its excellent comprehensive performance. First, from a cost perspective, chopped strand mat is more economical than materials such as metal or synthetic resin. Secondly, it has good mechanical strength and tensile strength, and is not easy to deform even under heavy pressure. More importantly, chopped strand mat has excellent corrosion resistance and can work stably for a long time in acid and alkali environments without damage. In addition, the material also has good thermal insulation and insulation properties, and is suitable for making thermal insulation pads, electrical components, etc. The most important point is that chopped strand mat is easy to process and can be cut into any shape and size according to actual needs, which greatly facilitates the production and installation process. These characteristics together determine the irreplaceability of chopped strand mat in many scenarios.

What practical problems can fiberglass chopped strand mat solve?

The application of fiberglass chopped strand mat is very extensive, covering almost all manufacturing fields. In the construction industry, it can be used as part of the roof waterproofing layer to effectively prevent rainwater from penetrating and extend the service life of the building.

In the field of automobile manufacturing, chopped strand mat is used to make thermal insulation pads to improve driving comfort. In addition, it can also be used to reinforce composite materials and enhance the rigidity and toughness of plastic products.

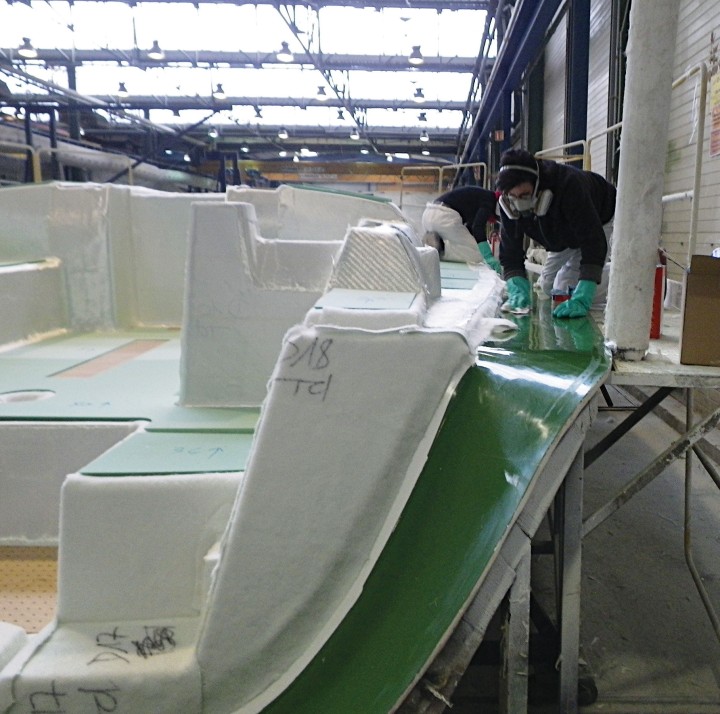

For the shipbuilding field, fiberglass chopped strand mat is equally important. In the manufacturing and maintenance stages of ship equipment, chopped strand mat also plays an important role. Due to its good anti-corrosion properties, chopped strand mat is used as the base layer of coating or covering in the shipbuilding process to enhance the adhesion and anti-corrosion effect of the coating. Especially on the outside of the hull, deck and other parts susceptible to seawater erosion, the application of chopped strand mat can effectively extend the service life of the ship and meet the safety requirements of maritime navigation. In short, whether in daily life or on industrial production lines, chopped strand mat is an ideal material for solving a variety of practical problems.

How does fiberglass chopped strand mat adapt to different use environments?

Fiberglass chopped strand mat is highly adaptable and can maintain its excellent performance in a variety of environments. It can maintain stability over a wide temperature range and can work normally from the cold Arctic to the hot desert areas. This material is usually made of glass fiber or synthetic fiber, so it has good weather resistance and aging resistance. Even when exposed to sunlight or humid air, chopped strand mat will not easily degrade. In addition, it is resistant to corrosion by most chemicals and is suitable for special workplaces such as chemical plants. In short, whether outdoors or indoors, whether under high or low temperature conditions, chopped strand mat can function reliably.

What unexpected benefits can be brought by using chopped strand mat?

In addition to its basic functions, chopped strand mat also brings many additional values. First, it is a green and environmentally friendly material that can be recycled and reused, which meets the requirements of modern society for sustainable development. Secondly, due to its good softness, it can fit complex surfaces, so it is very convenient when making models or handicrafts. In addition, chopped strand mat also has certain flame retardant properties, which can slow down the spread of fire and protect personnel safety when a fire occurs. Last but not least, it also has good sound absorption effect and can be used to make sound-absorbing panels or carpets to improve the indoor acoustic environment. These additional benefits make chopped strand mat more diversified in practical applications.

How to ensure the quality of chopped strand mat?

The key to ensuring the quality of chopped strand mat lies in strict production and testing processes. During the production process, qualified raw materials must be selected and processed with advanced production processes. After that, the finished product needs to be fully inspected for quality, including but not limited to measurements of dimensional accuracy, density uniformity, surface smoothness, etc. In addition, mechanical property tests such as tensile strength and bending strength are required to verify whether the material meets the expected standards. Finally, for batch-produced chopped strand mats, third-party certification should be carried out regularly to ensure that they continue to comply with relevant national standards or industry specifications.

What details should be paid attention to when purchasing fiberglass chopped strand mats?

Before purchasing chopped strand mats, there are several important details to pay attention to. The first is to determine the required specifications, including parameters such as thickness, width, and length, to ensure that the purchased products can meet the actual use needs. The second is to understand the strength and background of the supplier, and give priority to those companies with good reputation and rich experience. In addition, ask whether customized services are provided, because different application scenarios may require chopped strand mats with different characteristics. Finally, do not ignore the importance of after-sales service, and choose suppliers who can provide timely technical support and maintenance services so that problems encountered during use can be quickly resolved.

What innovative applications will chopped strand mats have in the future?

With the advancement of science and technology and the changes in market demand, the application prospects of chopped strand mat are very broad. In the future, we can foresee that chopped strand mat will be used in more emerging fields. For example, in the manufacturing of new energy vehicles, chopped strand mat may be used to enhance the protective performance of the battery pack shell; in the aerospace industry, it may be used to make lightweight and efficient aircraft parts; even in the field of medical health, chopped strand mat may develop new medical materials. With the deepening of research and the advancement of technology, chopped strand mat will surely show more surprising new uses and promote the development of related industries.

In Conclusion

By answering the above seven questions, I believe you have a deeper understanding of chopped strand mat. Whether from its unique performance characteristics or future application prospects, chopped strand mat is a high-quality material worth investing in. If you are looking for a reliable and versatile solution, then chopped strand mat is undoubtedly your ideal choice.